- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

2025 Top Trends in Pressure Fittings for Industrial Applications

The industrial landscape is ever-evolving, with technology and innovation driving significant changes in various applications. One critical component that often goes unnoticed but plays a vital role in ensuring efficiency and safety in various industrial processes is pressure fittings. These essential components are utilized to connect pipes, tubes, and hoses, withstanding high pressure and temperature to maintain the integrity of fluid transfer systems. As we look toward 2025, the trends emerging in pressure fittings are not only shaping their manufacturing and application but also influencing the entire industrial sector.

This overview will explore the top trends in pressure fittings anticipated for 2025, highlighting advancements in materials, design, and manufacturing processes. With an emphasis on sustainability and improved performance, industries are increasingly focusing on innovative solutions that enhance reliability while reducing environmental impact. The integration of smart technologies and automation is also set to revolutionize how pressure fittings are utilized, paving the way for smarter, more efficient systems. By understanding these trends, stakeholders can better prepare for the future, ensuring their projects leverage the best in pressure fittings technology for optimal productivity and safety.

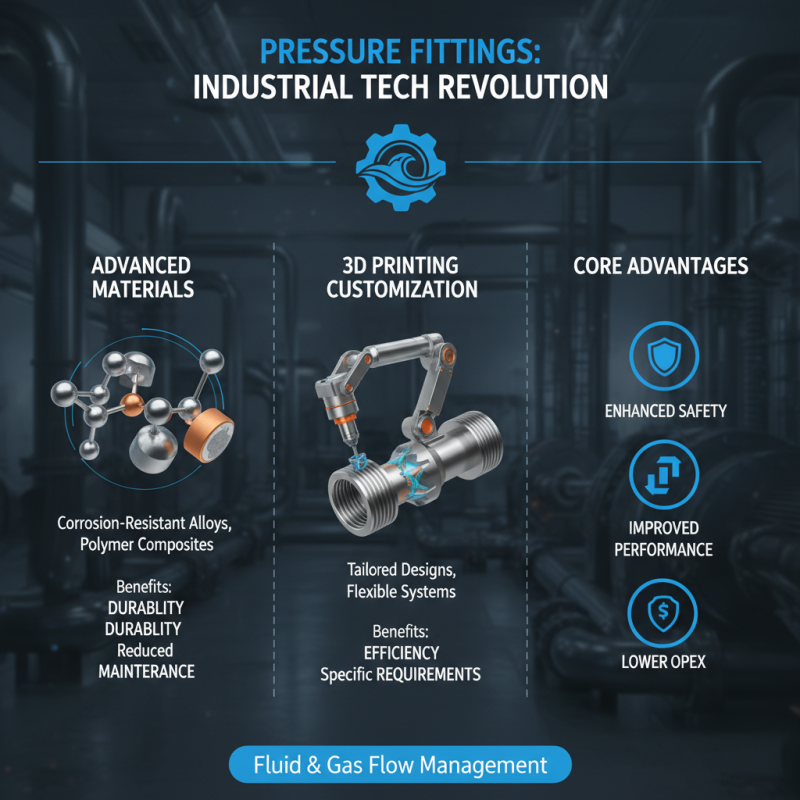

Emerging Technologies in Pressure Fittings for Industrial Use

Emerging technologies in pressure fittings for industrial use are poised to revolutionize the way industries manage fluid and gas flow. With a commitment to enhancing safety, performance, and efficiency, the development of advanced materials such as corrosion-resistant alloys and polymer composites is gaining traction. These materials not only provide greater durability but also reduce maintenance costs, ultimately leading to lower overall operational expenses. Moreover, innovations such as 3D printing technology enable the production of customized fittings that meet specific design requirements, allowing for more flexible and efficient piping systems.

Another key trend is the integration of smart technology into pressure fitting systems. The incorporation of sensors and IoT devices is facilitating real-time monitoring of pressure levels, leakage detection, and system performance analytics. This level of connectivity empowers industries to proactively address potential issues before they escalate, enhancing operational reliability and safety. Furthermore, predictive maintenance powered by artificial intelligence is optimizing the lifecycle management of pressure fittings, ensuring that replacements and repairs are conducted in a timely manner, thus minimizing downtime and inefficiencies in industrial operations.

Sustainability Trends Influencing Pressure Fitting Design

As industries evolve, the emphasis on sustainability continues to reshape the design of pressure fittings for industrial applications. The trend toward eco-friendly solutions is driven by increasing regulatory pressures and the growing awareness of climate change impacts. According to a recent report by the International Energy Agency (IEA), transitioning to sustainable industrial practices could reduce greenhouse gas emissions by up to 70% by 2050. This statistic underscores the urgency for manufacturers to prioritize green designs in their pressure fittings, which play a critical role in fluid and gas transport across various sectors.

Sustainable pressure fittings are being developed with materials that not only meet performance standards but also lower environmental footprints. For example, using advanced polymers and recyclable materials helps decrease waste at the end of a product’s lifecycle. Moreover, the adoption of efficient manufacturing processes can minimize energy consumption, further contributing to a product’s sustainability profile. A report from the American Society of Mechanical Engineers (ASME) indicates that up to 30% of industrial emissions can be linked to inefficient fittings and systems. Thus, innovation in pressure fitting designs not only enhances operational efficiency but is also a significant step towards achieving broader sustainability goals.

The focus on sustainability is not just a trend but a fundamental shift in how pressure fittings are designed, manufactured, and utilized within industrial applications. By embracing sustainable practices, industries can enhance their competitive advantage while contributing positively to global environmental objectives.

Innovations in Materials for Enhanced Pressure Fitting Performance

The industrial sector is on the brink of significant advancements in pressure fitting technologies, particularly through innovations in materials. One of the most compelling trends is the shift towards lightweight composite materials that not only reduce the overall weight of fittings but also enhance their durability. These composites are engineered to withstand extreme pressure and temperature variations, making them ideal for applications in oil and gas, chemical processing, and manufacturing. Their corrosion resistance properties further extend their lifespan, providing long-term cost savings and reliability.

In addition to composites, advanced polymers are gaining traction for their flexible yet robust characteristics. These materials are being designed to offer superior sealing capabilities, which are essential in preventing leaks in high-pressure environments. With the integration of smart materials that can dynamically respond to environmental changes—such as temperature shifts or pressure fluctuations—manufacturers are significantly improving the efficiency and safety of pressure fittings. Such innovations not only optimize performance but also contribute to sustainability efforts by reducing the need for frequent replacements and the resulting waste.

2025 Top Trends in Pressure Fittings for Industrial Applications

This chart illustrates the innovations in materials that are enhancing pressure fitting performance in industrial applications. The data showcases the increasing adoption of advanced materials over recent years and their projected trends through 2025.

Automation and Smart Technology Integration in Pressure Fittings

As the industrial landscape evolves, the integration of automation and smart technology in pressure fittings is paving the way for enhanced efficiency and safety in various applications. Smart pressure fittings equipped with sensors enable real-time monitoring of pressure and temperature, allowing for proactive maintenance and reducing the risk of system failures. Such technology not only minimizes downtime but also optimizes operational performance by providing valuable data that can be analyzed for continuous improvement.

Furthermore, the adoption of automation in pressure fitting systems allows for streamlined processes and improved accuracy in handling pressure-related tasks. Automated systems can adjust parameters on-the-fly, responding to changes in the operational environment without human intervention. This level of responsiveness significantly contributes to maintaining optimal conditions and ensuring compliance with safety standards. As industries increasingly embrace Industry 4.0 principles, the role of smart technology in enhancing the reliability and intelligence of pressure fittings will become even more pronounced, transforming traditional approaches to industrial applications.

Regulatory Changes Impacting Pressure Fitting Standards and Practices

Regulatory changes play a crucial role in shaping the standards and practices surrounding pressure fittings in industrial applications. As industries continue to evolve, regulatory bodies are responding to the need for improved safety, efficiency, and environmental sustainability. Recent updates in regulations emphasize stricter compliance and enhanced quality control measures for pressure fittings, ensuring that they meet rigorous safety and performance standards. These changes are not only aimed at protecting workers and the environment but also at streamlining processes within various sectors, such as oil and gas, chemicals, and manufacturing.

Moreover, these regulatory adjustments are prompting industries to adopt innovative practices in the design and use of pressure fittings. Companies are investing in advanced materials and production technologies to meet or exceed new standards, which often require features such as increased corrosion resistance and improved structural integrity. As a result, organizations are also prioritizing training and skill development for their workforce to ensure a thorough understanding of the latest compliance requirements and the associated technologies. This focus on adaptation to regulatory changes is essential for maintaining competitiveness and ensuring long-term operational success in the industrial sector.

2025 Top Trends in Pressure Fittings for Industrial Applications - Regulatory Changes Impacting Pressure Fitting Standards and Practices

| Trend | Description | Regulatory Impact | Expected Changes |

|---|---|---|---|

| Increased Automation | Automation of joining processes for pressure fittings is on the rise. | New standards to ensure safety in automated processes. | Review of automation machinery protocols. |

| Material Advances | Use of advanced materials to improve performance and longevity. | Revisions to material testing standards. | Enhanced certification processes for materials. |

| Sustainability | Focus on eco-friendly manufacturing processes for fittings. | Emergence of regulations targeting carbon footprint reduction. | Mandatory sustainability reporting. |

| Smart Fittings | Integration of IoT technology into pressure fittings. | Need for compliance with data security regulations. | Protocols for data management and privacy. |

| Global Standardization | Harmonization of pressure fitting standards across regions. | Adjustments required for compliance across markets. | Training and adaptation to new standards. |

Related Posts

-

How to Choose the Right Pressure Fittings for Your Plumbing Needs

-

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

-

Why High Pressure Fittings Are Essential for Safe Industrial Applications

-

How to Choose the Right Pipe Plug for Your Plumbing Needs

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project