- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

How to Choose the Right Gas Pipe Fittings for Your Home Projects

Choosing the right gas pipe fittings for your home projects can greatly influence the safety and efficiency of your gas systems. According to industry expert James Anderson, a certified gas technician, “Selecting the proper gas pipe fittings is crucial not only for the functionality of your systems but also for ensuring safety and compliance with regulations.” This statement underscores the importance of understanding the various types of fittings available and their specific applications in residential gas installations.

When embarking on any gas-related project, homeowners need to consider factors such as the type of gas being used, the pressure requirements, and the compatibility of materials, all of which play a critical role in the selection of gas pipe fittings. Incorrect choices can lead to leaks, inefficiencies, and potential hazards. Anderson emphasizes that “knowledge is power in this field,” suggesting that individuals equip themselves with essential information before making any decisions.

In this guide, we will explore the various types of gas pipe fittings, their appropriate uses, and tips for making informed decisions tailored to your home projects. Understanding these elements will not only enhance your project's success but also ensure peace of mind in knowing that your gas systems are safe and reliable.

Understand the Different Types of Gas Pipe Fittings Available

When tackling home projects involving gas lines, understanding the different types of gas pipe fittings is crucial for ensuring safety and functionality. The most common types of gas pipe fittings include elbows, tees, couplings, and unions. Elbows are used to change the direction of the gas flow, making them essential for navigating around obstacles. Tees allow for branching off the main line, which can be beneficial when directing gas to different appliances. Couplings serve to connect two pieces of pipe together, ensuring a secure link without altering the direction of the flow.

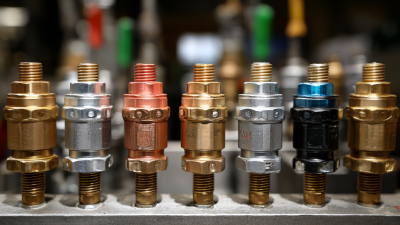

Moreover, materials are a key factor in selecting the right gas pipe fittings. Fittings can be made from various materials, including brass, steel, and plastic, each with its own advantages and limitations. Brass fittings are resistant to corrosion and provide a durable option, while steel fittings are often chosen for their strength in high-pressure applications. Plastic fittings, on the other hand, may be suitable for low-pressure systems and are lightweight, but they require careful consideration regarding compatibility with gas usage. Understanding these differences can guide you in making informed decisions that enhance both the safety and efficiency of your home gas systems.

Gas Pipe Fittings Types and Their Usage

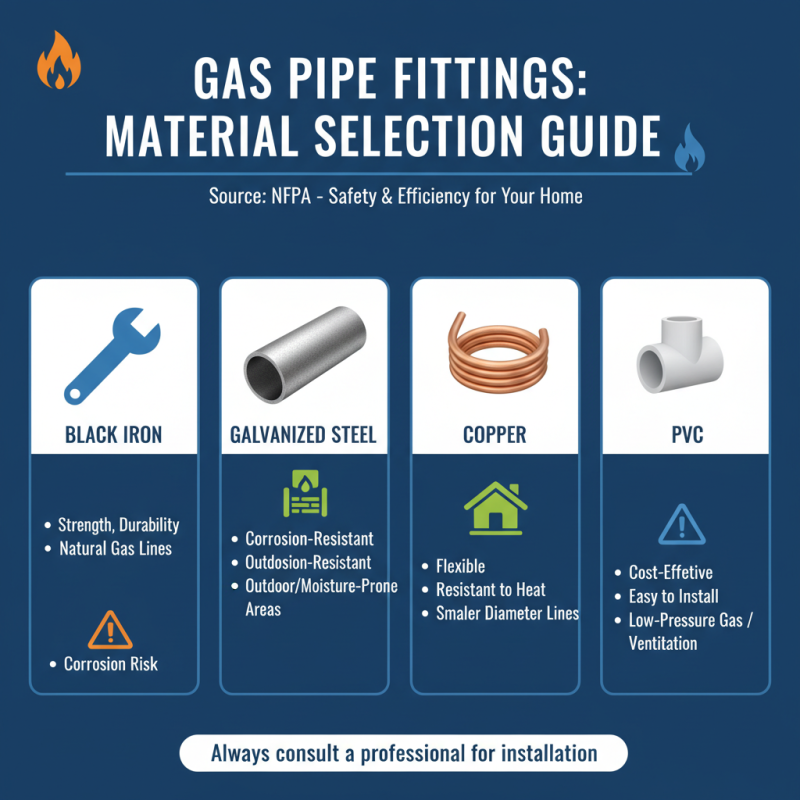

Assess the Material Options for Gas Pipe Fittings

When selecting gas pipe fittings for your home projects, it's crucial to assess the various material options available to ensure safety and efficiency. Common materials include black iron, galvanized steel, copper, and PVC, each offering distinct advantages and applications. According to the National Fire Protection Association (NFPA), black iron is widely used for natural gas lines due to its strength and durability but requires proper installation to prevent corrosion and leaks.

Galvanized steel is another popular choice, often preferred for its protective coating that resists rust—a significant factor, considering that over 50% of gas line failures are attributed to corrosion, as reported by the American Gas Association. Meanwhile, copper fittings are lauded for their ease of installation and reliability in smaller gas systems. However, it's important to note that not all copper materials are suitable for gas lines, as specific types are required to ensure compliance with safety standards. PVC, while versatile and cost-effective for water pipes, is not recommended for gas applications due to its lower heat resistance and strength.

In evaluating these materials, homeowners should also consider local building codes and regulations, which often dictate the types of materials permissible for use in gas piping systems. By understanding the properties and applications of each material, you can make informed decisions that align with safety standards and project requirements.

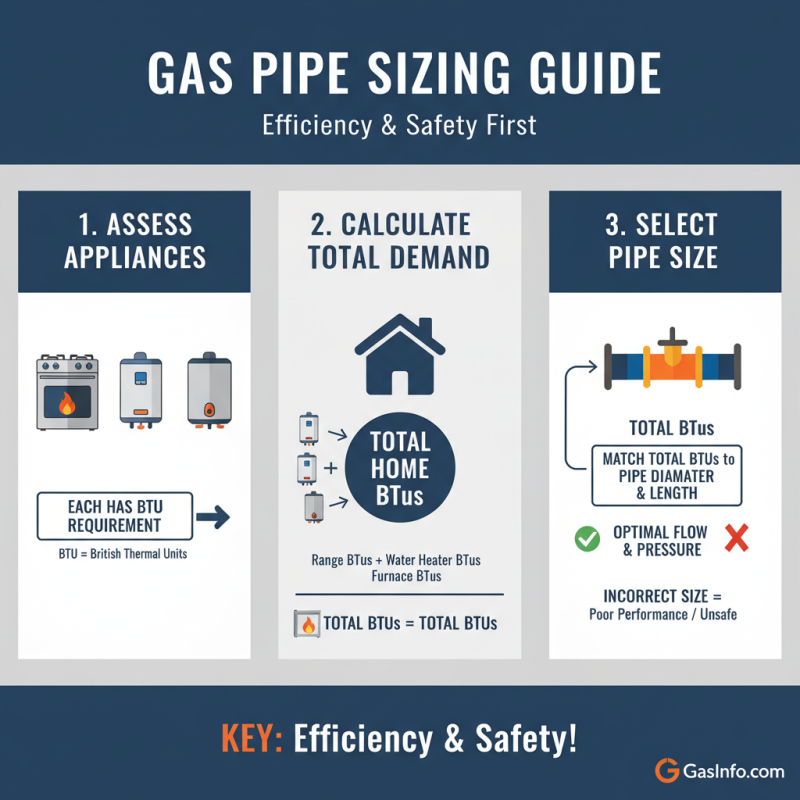

Determine the Size Requirements for Your Gas Pipe System

When embarking on a gas pipe installation project, determining the appropriate size for your gas pipe system is pivotal for ensuring efficiency and safety. The size of the gas fittings directly affects the flow rate, pressure drop, and overall functionality of your gas system. Start by assessing the type of appliances that will be connected to the gas line, as each appliance has specific gas consumption requirements measured in BTUs (British Thermal Units). This understanding will help you calculate the total BTU demand for your home, guiding you in selecting the right size for your gas pipes.

To accurately determine the size requirements, you'll need to consider factors such as the distance from the gas meter to the appliances, the number of connections, and the elevation changes in your piping path. These elements can influence the gas pressure and flow rate, making it essential to use guidelines or charts that correlate BTU load with pipe size based on the type of gas being used. Additionally, ensure that you account for any local codes or regulations that could dictate certain requirements for gas installation, helping you to choose fittings that not only meet your project needs but also adhere to safety standards.

Learn About Safety Standards and Regulations for Gas Fittings

When it comes to selecting gas pipe fittings for home projects, understanding safety standards and regulations is paramount. According to the American Society of Mechanical Engineers (ASME), compliance with relevant codes such as the International Gas Code (IGC) ensures that materials used for gas systems withstand operational pressures and prevent leaks. The IGC emphasizes using approved materials and fittings that can handle gas pressure without risk of failure.

For instance, it defines requirements for various types of joints, corrosion resistance, and the application of certain fitting designs, which are critical for maintaining safety in residential settings.

Furthermore, the National Fire Protection Association (NFPA) sets forth guidelines that underscore the importance of proper installation techniques and regular maintenance of gas fittings to mitigate the risk of accidents. A report from the NFPA highlights that nearly 68% of gas-related accidents in homes could be avoided through adherence to these regulations. This stresses the need for homeowners to not only choose the right materials but also ensure proper installation, often best handled by licensed professionals familiar with local codes. Staying informed about these safety standards not only protects your investment but also safeguards the health and safety of all occupants in the home.

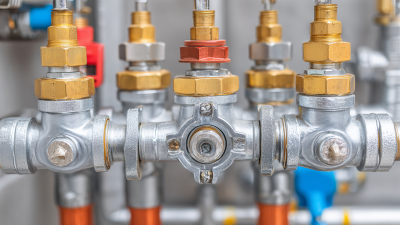

Consider Installation Techniques and Tools Needed for Success

When embarking on home projects that involve gas pipe fittings, understanding installation techniques and the necessary tools is crucial for ensuring safety and efficiency. According to the National Fire Protection Association (NFPA), improper installation of gas piping systems can lead to hazardous leaks, with over 10,000 reported gas-related incidents annually in the U.S. alone. Therefore, it is essential to familiarize yourself with the standardized installation methods recommended by industry experts, which consist of proper measurement, cutting, and securing of the fittings.

A well-equipped toolbox is fundamental for successful installation. Essential tools include a pipe wrench for securing fittings tightly while avoiding over-tightening, which can damage the threads. Additionally, a pipe cutter ensures clean cuts, reducing the risk of leaks. Professional guidance from sources like the American Gas Association emphasizes the importance of using sealing compounds and joint compounds that are compatible with gas pipes to further minimize leakage risks. Such practices can significantly contribute to reducing maintenance costs, with the Gas Technology Institute noting that regular inspections and using reliable fittings can decrease the likelihood of repairs by up to 30%.

How to Choose the Right Gas Pipe Fittings for Your Home Projects

| Fitting Type | Material | Common Uses | Installation Technique | Tools Needed |

|---|---|---|---|---|

| Coupling | Steel | Connecting two pipes | Welding or Threading | Pipe wrench, tape |

| Elbow | Brass | Changing pipe direction | Soldering or Compression | Soldering iron, flux |

| Tee | PVC | Branching off a pipe | Glues and Solvent welding | Pipe cutter, solvent cement |

| Valve | Stainless Steel | Control flow of gas | Welding or Screwing | Wrench, thread seal tape |

| Cap | Copper | Stopping pipe flow | Soldering | Soldering iron, torch |

Related Posts

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency

-

2025 Top Gas Pipe Fittings Essential Guide for Homeowners and Professionals

-

Understanding Gas Fittings: A Comprehensive Guide to Safety and Installation Best Practices

-

7 Essential Tips for Choosing Gas Fittings: Safety Standards and Best Practices

-

Why Tube Fittings Are Essential for 70% of Industrial Fluid Systems Efficiency

-

How to Choose the Right Needle Valves for Your Industrial Applications