- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

How to Choose the Right Hose and Fittings for Your Needs

Choosing the right hose and fittings is crucial for any project. As John Smith, a leading expert in the hose and fittings industry, once said, "The right combination is the foundation of efficiency." This statement underscores the importance of selecting appropriate materials and designs that cater to specific needs.

Hoses and fittings come in various shapes and sizes. Each type serves a unique purpose, from gardening to industrial applications. Different environments demand different materials. Rubber and PVC hoses can perform differently under pressure or temperature extremes. Users often face confusion when presented with multiple options.

It's easy to overlook small details, like fitting compatibility. Misalignment can lead to significant issues down the line. Moreover, not all hoses are made equal; some might wear out quickly. Understanding your requirements is vital. Reflecting on these choices can lead to better decision-making in the long run.

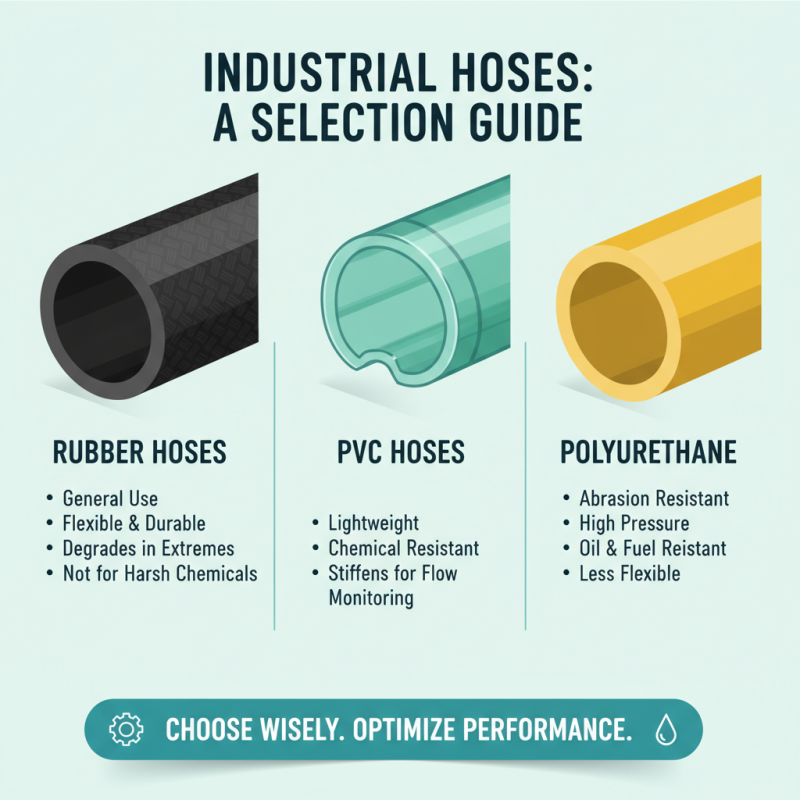

Understanding Different Types of Hoses and Their Applications

When selecting a hose for your project, it's crucial to understand the various types available. Rubber hoses are common for general use. They offer flexibility and durability. However, they can degrade in extreme conditions and may not be the best choice for every task. PVC hoses are lightweight and resistant to chemicals, yet they can become stiff in cold weather. This is an important consideration when making your choice.

For heavy-duty applications, consider reinforced hoses. These are designed to withstand higher pressures and rough environments. They often have a stronger structure, providing peace of mind. On the other hand, garden hoses provide basic functionality but might lack durability over time. It’s tempting to go for the cheapest option, but that can be a mistake. Think about the long-term implications. If you often replace cheaper hoses, are you really saving money?

Additionally, pay attention to the fittings. The right connectors are vital for optimal performance. Compatibility issues can lead to leaks or kinks. It's easy to overlook this detail, but it can ruin a project. Assess your specific needs carefully. Understanding these options can save you trouble down the line. Each type serves a purpose, but not all will meet your unique requirements.

Identifying the Right Hose Material for Your Specific Needs

Choosing the right hose material is crucial for various applications. Different materials have unique properties. For instance, rubber hoses are flexible and durable, making them ideal for transportation tasks. Thermoplastic hoses have excellent temperature resistance, but can be less flexible than rubber. Consider what you need before deciding.

Next, think about the environment. Will the hose be exposed to chemicals? A PVC hose may work. However, if it's for high-temperature use, that’s a different story. Metal hoses can handle extreme heat but lack flexibility. Evaluate your specific conditions closely; it’s easy to overlook this aspect.

Reflect on the performance over time. Some materials degrade faster than others. Choosing the wrong hose can lead to frequent replacements. This can be frustrating and costly. It's essential to match your needs with the right material. Don’t rush this decision—adequate research pays off in the long run.

How to Choose the Right Hose and Fittings for Your Needs - Identifying the Right Hose Material for Your Specific Needs

| Hose Material | Temperature Range (°F) | Pressure Rating (PSI) | Chemical Resistance | Common Applications |

|---|---|---|---|---|

| PVC | -20 to 150 | 300 | Weak in solvents | Water transfer, irrigation |

| Rubber | -40 to 190 | 500 | Good resistance to oils | Automotive, industrial |

| Polyurethane | -50 to 160 | 300 | Excellent abrasion resistance | Compressed air, water |

| Silicone | -80 to 400 | 150 | Limited chemical resistance | Food grade, medical |

| Stainless Steel | -420 to 1500 | 3000 | Excellent corrosion resistance | Chemical processing, high-pressure |

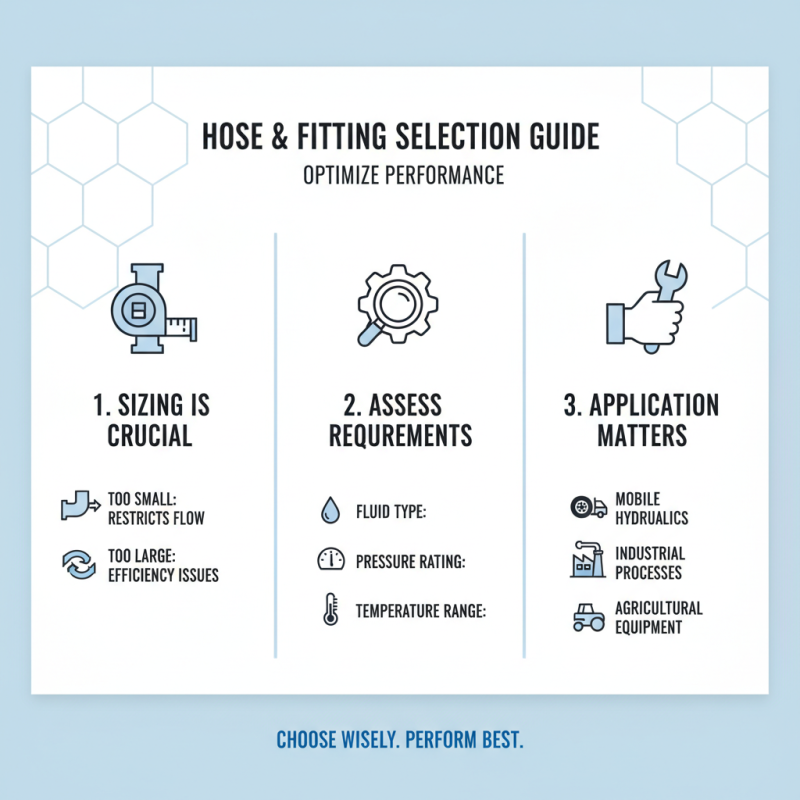

Exploring Various Fitting Types and Compatibility

When selecting hose fittings, compatibility is key. Different types of fittings serve distinct purposes. For example, quick-connect fittings allow fast assembly and disassembly. This can save time and reduce wear. However, not all hoses accommodate them well. Some hoses require specific fitting types for optimal performance.

Industry reports indicate that mismatched fittings lead to 30% more leaks. These leaks can potentially result in costly downtime. It’s crucial to know the hose's pressure rating and the environment it will operate in. Temperature and chemical exposure matter greatly in fitting compatibility. A fitting made for one application may fail in another.

Consider the size as well. Even slight variations can hinder flow efficiency. Many people overlook this detail. They assume all fittings are universal. In reality, standards differ widely. Regularly reviewing compatibility guidelines can help. It’s essential to prioritize safety. A simple mistake can lead to catastrophic results.

Hose and Fitting Types Compatibility

Guidelines for Sizing Hoses and Fittings Appropriately

Choosing the right hoses and fittings can be tricky. Sizing is crucial for optimal performance. A hose that is too small may restrict flow, while one that is too large could lead to efficiency issues. Assess the specific requirements of your application. Consider the fluids you will be transporting, as well as the pressure and temperature they will encounter.

Measuring diameter accurately is essential. Use calipers or a measuring tape. If you're unsure, always err on the side of caution. Additionally, inspect the fittings carefully. Poor connections can cause leaks. Look for signs of wear and ensure compatibility with your hose. It’s also important to think about the environment. A fitting that works well indoors may fail outside.

Keep in mind that your initial choice may not always be correct. Testing various hoses and fittings can reveal surprising results. Monitor your setup after installation. Small adjustments can make a big difference. Experimentation can help you find the best fit for your needs, leading to better efficiency and performance over time.

Tips for Ensuring Proper Hose and Fitting Installation and Maintenance

Choosing the right hose and fittings is crucial for effective operation. However, installation and maintenance can easily be overlooked. Ensuring the correct setup can save time and prevent future issues.

When installing hoses, always check for proper alignment. Misalignment can lead to leaks and wear. Tighten fittings securely without overdoing it. Over-tightening can damage the hose. Remember to inspect regularly. Look for cracks, fraying, or other signs of wear.

Maintenance is just as important. Clean hoses and fittings to prevent buildup. Dirt and debris can cause blockages. When storing hoses, coil them neatly to avoid kinks. Kinks weaken hoses over time. Regular check-ups will help maintain function and longevity. It’s easy to forget these steps, but they matter. Neglect can result in costly repairs. Proper care leads to better performance.

Related Posts

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

Why High Pressure Fittings Are Essential for Safe Industrial Applications

-

How to Choose the Right Pressure Fittings for Your Plumbing Needs

-

2025 Top Trends in Pressure Fittings for Industrial Applications

-

Why Choosing the Right AN Hose Fittings is Essential for Your Performance Upgrades

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project