- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

10 Tips for Choosing the Right Hose and Fittings for Your Project?

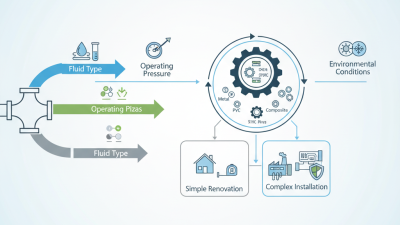

Choosing the right hose and fittings for your project can seem daunting. Each project has unique requirements. A wrong choice can lead to leaks or system failures. Understanding your materials is critical. Rubber, PVC, and silicone hoses each serve different purposes. They handle varying pressures and temperatures.

Fittings are just as important as hoses. They connect hoses securely to prevent leaks and disconnects. The wrong fitting can lead to catastrophic results. Look for compatibility with your hose material. Thread types and sizes must match.

Don’t overlook the environment where your hose and fittings will operate. Extreme temperatures or chemical exposure can affect performance. Regularly check hoses for wear and tear. Sometimes, what seems like a small issue can escalate into a larger problem. Take your time, research, and plan carefully for the best results.

Understanding the Different Types of Hoses and Their Applications

When selecting hoses for your project, understanding their types is crucial. There are various hoses, each designed for specific applications. For instance, PVC hoses are lightweight and suitable for general-purpose use. They are often used in gardening and irrigation settings. Conversely, rubber hoses are ideal for high-pressure needs. Their durability makes them perfect for industrial applications. According to a recent industry report, the global hose market is projected to reach $15.81 billion by 2026, driven by increased construction activities.

The choice of fittings is also critical. Metal fittings are robust and often preferred in high-pressure environments. On the other hand, plastic fittings are lighter and more affordable. However, they may not be suitable for high-temperature tasks. A poorly chosen fitting can lead to leaks, increasing costs. Research indicates that improper hose and fitting combinations can lead to a 30% increase in failure rates. Thus, assessing the requirements of your specific project is vital. Balancing budget and quality can be tricky, but it's essential to aim for the best fit.

Factors to Consider When Selecting Hose Materials

Selecting the right hose material is crucial for any project. Different projects require different materials. Common options include rubber, PVC, and polyurethane. Each comes with its own set of advantages and disadvantages. For instance, rubber hoses are often flexible and durable, but they can deteriorate in extreme weather.

Consider the working environment. Will the hose be exposed to chemicals? If so, ensure the material is compatible. PVC can handle mild chemicals but may not stand up to strong solvents. Polyurethane is more resistant, but it can be pricier. Evaluate the temperature range. Some materials perform poorly in high or low temperatures.

Weight is another factor to think about. Lightweight hoses are easier to handle but may not endure heavy-duty tasks. Don’t overlook the type of fittings required. Ensure they match your hose material. Improper fittings can lead to leaks, wasting both time and resources. Reflect on the project’s specific needs to avoid pitfalls in your selection.

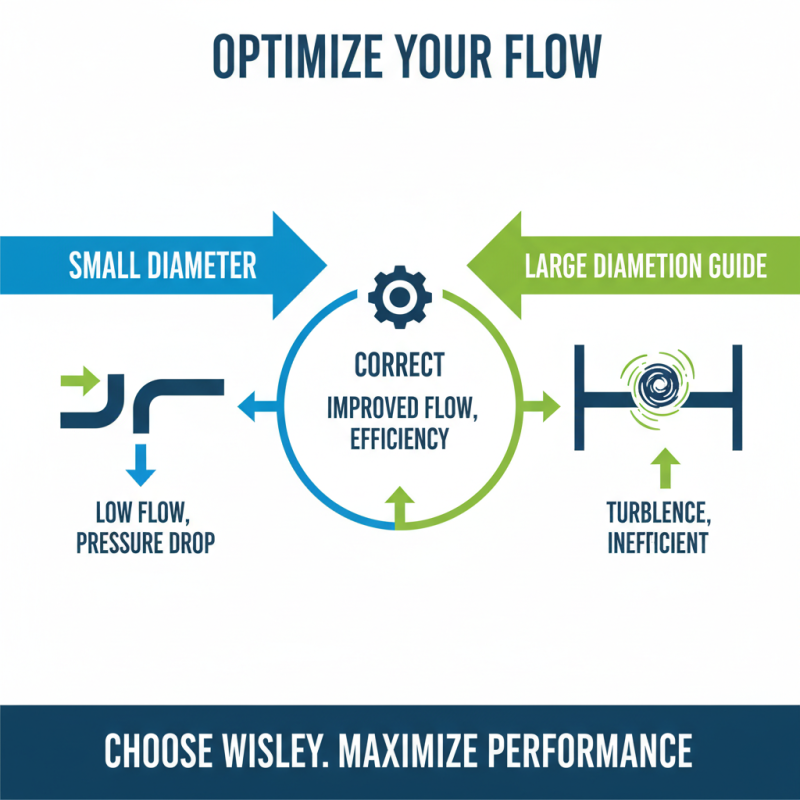

How to Determine the Correct Hose Diameter for Your Needs

Selecting the correct hose diameter is crucial for any project. A well-chosen diameter can improve flow rates and efficiency. Too small a diameter can restrict flow, leading to pressure drops. Conversely, a hose that is too large may create turbulence, which is not ideal.

When determining the right diameter, consider your project’s requirements. What type of fluid are you working with? Is it thick or thin? Measure the flow rate needed. A heavier liquid may require a larger diameter. Additionally, think about the length of the hose. Longer hoses with narrow diameters can experience significant pressure loss.

It’s also helpful to visualize the application context. If you’re watering a garden, a wider hose can deliver water faster. However, a too-wide hose might be unwieldy. Reflect on the balance between flexibility and capacity. Choosing the right size can be tricky. Take time to analyze your needs and the project environment. A wrong choice here can lead to frustration later on.

Choosing the Right Fittings for Optimal Performance

Choosing the right fittings is vital for optimal performance. Poor-fitting components can lead to leaks, pressure drops, and even equipment failure. A study by the American Society of Mechanical Engineers (ASME) indicates that improper fittings are responsible for nearly 30% of system inefficiencies in industrial applications. This statistic underscores the importance of careful selection.

Material choice is crucial. For high-pressure systems, robust materials such as stainless steel or reinforced plastics are often recommended. Lightweight options may seem appealing, yet they can compromise durability. An analysis by the Institute of Fluid Power suggests that using unsuitable materials can reduce lifecycle performance by up to 40%. This is a concrete reminder to prioritize quality over convenience.

Don’t overlook the size of the fittings. Mismatched sizes can disrupt flow rates, leading to operational headaches. When selecting fittings, consider the hose diameter, type of fluid, and application conditions. Remember, even a minor oversight can escalate into major issues down the line. Ensuring a proper fit might require consulting industry guidelines or seeking expert advice. Taking time during this phase pays off in the long run.

10 Tips for Choosing the Right Hose and Fittings for Your Project

| Tip Number | Tip | Description |

|---|---|---|

| 1 | Identify Pressure Requirements | Determine the maximum pressure your system will encounter to select the right hose that can withstand it. |

| 2 | Consider the Fluid Type | Ensure that the hose material is compatible with the fluids being transported to avoid chemical degradation. |

| 3 | Check Temperature Ratings | Select hoses and fittings that can operate within the temperature range of your application. |

| 4 | Assess Bend Radius | Make sure the hose can handle bends without kinking, which can restrict flow and damage the hose. |

| 5 | Evaluate Length Requirements | Choose the length of the hose carefully to avoid excess strain and ensure proper connectivity. |

| 6 | Select the Right Fittings | Ensure fittings match the hose ID and are suitable for the application based on pressure and temperature. |

| 7 | Choose Durable Materials | Opt for materials that provide excellent durability and resistance against wear and tear in your working environment. |

| 8 | Consider Weight and Flexibility | Select hoses that are lightweight and flexible for easier handling without sacrificing performance. |

| 9 | Review Application Guidelines | Refer to industry standards and guidelines to ensure compliance with safety and performance metrics. |

| 10 | Perform Regular Maintenance | Inspect hoses and fittings regularly to detect any signs of wear, leaks, or damage early on. |

Safety Tips for Installing and Maintaining Hoses and Fittings

Installing and maintaining hoses and fittings requires careful attention to safety. According to industry reports, improper installation can increase the risk of accidents. About 20% of all equipment failures involve leaks or bursts, leading to hazardous situations. Regularly inspecting hoses for wear and damage is essential. A simple visual check can often reveal signs that a line may fail soon.

Lack of proper fittings can also pose safety risks. A study showed that over 30% of fluid-related injuries were linked to inadequate or faulty connections. Using the correct fittings for your hose type is essential for maintaining pressure and preventing leaks. If a fitting doesn't match well, it can cause dangerous failures under pressure.

Always wear protective gear during installation. Gloves and goggles can protect against splashes and sharp edges. Moreover, hydrostatic testing is recommended every five years for high-pressure hoses. This test verifies that hoses can withstand their rated pressure. Remember, neglecting maintenance can lead to serious accidents and costly downtime.

Related Posts

-

Maximizing Efficiency: The Future of Hose Fittings in Industrial Applications

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

Why Choosing the Right AN Hose Fittings is Essential for Your Performance Upgrades

-

Top Gas Valves for Home and Industrial Use You Need to Know

-

How to Choose the Right Pressure Fittings for Your Plumbing Needs

-

Top 10 Essential Plumbing Fittings Every Homeowner Should Know About