- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

How to Choose the Right Needle Valves for Your Industrial Applications

In the realm of industrial applications, the selection of appropriate needle valves is crucial for efficient process control and fluid regulation. Needle valves, known for their precision and reliability, serve as essential components in various systems, enabling the accurate adjustment of flow rates in both liquid and gas services. Their design allows for fine control, making them particularly advantageous in applications where minor variations can significantly impact performance or safety.

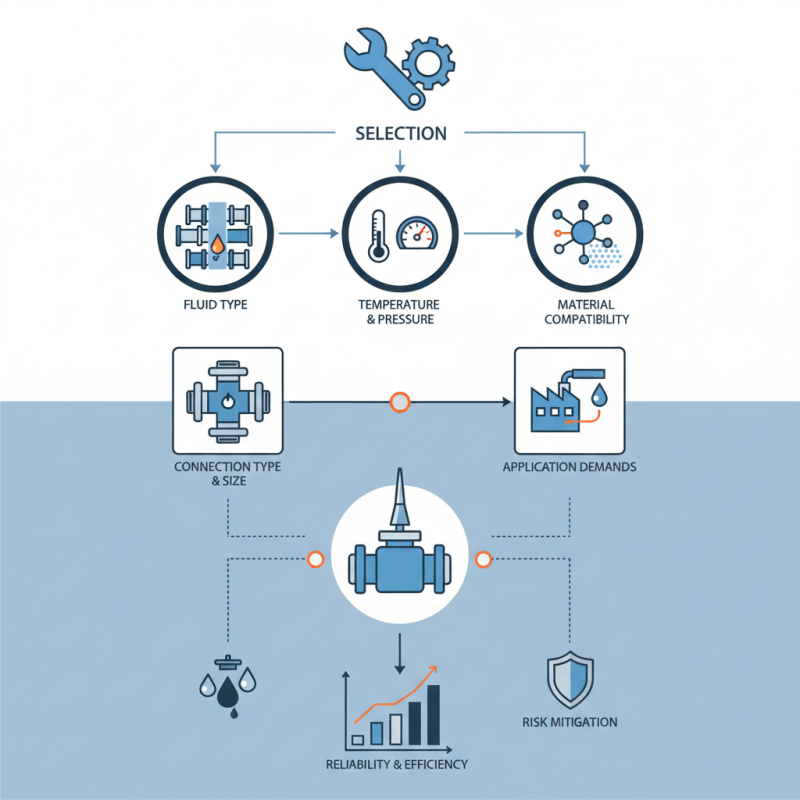

Choosing the right needle valves involves understanding numerous factors, including the specific demands of the application, the type of fluid being controlled, and the environmental conditions they will face. Factors such as material compatibility, pressure ratings, and temperature limits are paramount in ensuring the longevity and effectiveness of these valves. Furthermore, considerations like the valve's connection type and size play a pivotal role in guaranteeing seamless integration into existing systems, thereby optimizing performance and minimizing potential disruptions.

This guide aims to provide insights into the aspects that must be considered when selecting needle valves for industrial use, ensuring that operators can make informed decisions that will enhance the reliability and efficiency of their operations. By comprehending these elements, professionals can significantly mitigate risks and improve the overall functionality of their systems.

Understanding Needle Valve Types and Their Applications

When selecting the appropriate needle valves for industrial applications, it’s essential to understand the various types available and their specific functions. Needle valves are primarily designed for precision flow control in a variety of systems. Common types include standard needle valves, which provide good flow regulation, and pressure-seal needle valves, ideal for high-pressure applications. Additionally, there are other specialized designs such as bleed and isolation valves that cater to specific industry needs. Each type is crucial in maintaining optimal performance and safety in operations.

The applications of needle valves span several industries, including chemical processing, oil and gas, and water treatment. In chemical processing, for instance, needle valves facilitate careful adjustments of flow rates, ensuring the safe handling of reactive substances. Meanwhile, in oil and gas industries, they are often used in measurement and control processes due to their ability to respond to minimal changes in pressure. Understanding these applications helps in selecting the most suitable needle valve, ensuring efficiency and reliability in various operational environments.

Key Factors in Needle Valve Material Selection

When selecting needle valves for industrial applications, the material of the valve is a crucial factor that influences performance and durability. One of the first considerations is the chemical compatibility of the valve material with the fluids it will control. Common materials for needle valves include stainless steel, brass, and various plastics, each offering different strengths against corrosion, temperature fluctuations, and pressure variations. For instance, stainless steel is often preferred in corrosive environments due to its high resistance to rust and degradation, while plastic valves might be suitable for less demanding applications that don't involve severe conditions.

Another important aspect is the thermal stability of the valve material. In industries where temperature swings are frequent, selecting a needle valve material that maintains integrity under high-temperature and low-temperature extremes is vital. Suitable materials need to withstand these conditions without compromising the valve's sealing capability or structural integrity. Additionally, factors like the valve's pressure rating, environmental conditions, and maintenance requirements should also influence the choice of material, ensuring that it aligns perfectly with the specific needs of your application for optimal performance over time.

Material Selection for Needle Valves in Industrial Applications

Assessing Pressure and Temperature Ratings for Valves

When selecting needle valves for industrial applications, understanding pressure and temperature ratings is crucial. These ratings dictate the operational limits of the valves and are essential for ensuring safety and efficiency in various systems. The pressure rating indicates the maximum pressure that a valve can handle while maintaining its integrity and functionality. Typically measured in psi (pounds per square inch), this rating helps determine whether a valve is suitable for the specific conditions of your application, whether it involves fluids or gases under varying pressures.

Temperature ratings are equally important, as they define the thermal limits of the valve materials. Valves may be exposed to extreme temperatures, which can affect the performance and lifespan of the component. Selecting a valve with an appropriate temperature rating ensures that it will function reliably without the risk of failure due to thermal expansion or contraction. When assessing needle valves, it is vital to consider both pressure and temperature requirements in conjunction with the materials used in the valve construction, as this will ultimately affect the valve's durability and suitability for your specific industrial application.

How to Choose the Right Needle Valves for Your Industrial Applications

| Valve Type | Pressure Rating (psi) | Temperature Rating (°F) | Material | Connection Type |

|---|---|---|---|---|

| Stainless Steel Needle Valve | 6000 | -50 to 400 | Stainless Steel | Threaded |

| Bronze Needle Valve | 2500 | -20 to 300 | Bronze | Flanged |

| Carbon Steel Needle Valve | 3000 | -40 to 200 | Carbon Steel | Welded |

| PVC Needle Valve | 150 | 32 to 140 | PVC | Socket |

| Hastelloy Needle Valve | 6000 | -40 to 1000 | Hastelloy | Threaded |

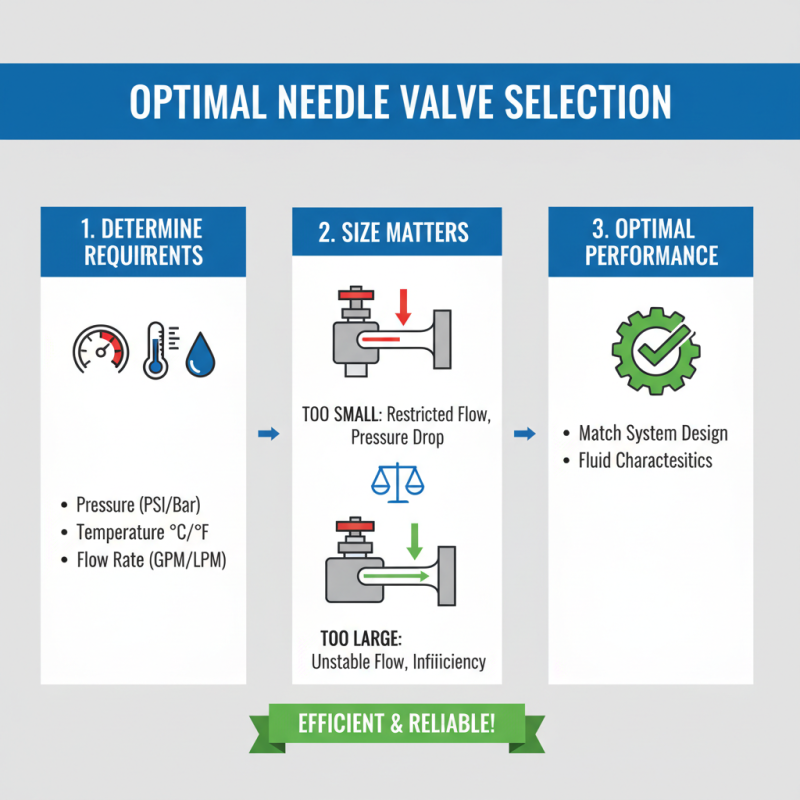

Determining the Right Size and Flow Rate for Your Needs

When selecting needle valves for industrial applications, it is crucial to determine the right size and flow rate to meet specific operational needs. The size of a needle valve is fundamentally linked to the system design and the characteristics of the fluid it controls. A valve that is too small may restrict flow and lead to increased pressure drops, while an oversized valve can result in unstable flow conditions and inefficiencies. Therefore, understanding the system's pressure, temperature, and flow requirements is essential to select a valve that ensures optimal performance.

Flow rate is another critical factor in choosing the right needle valve. The intended application often dictates the flow rate, which must be balanced against the valve's specifications. To calculate the necessary flow rate, considerations should include the maximum and minimum flow requirements, as well as the fluid's properties such as viscosity and density. Utilizing flow rate data, users can identify a needle valve with an appropriate Cv value, which indicates the valve's ability to allow fluid to pass through at a given pressure drop. By carefully assessing both size and flow rate, users can enhance system efficiency and accuracy in fluid control.

Best Practices for Installation and Maintenance of Needle Valves

In industrial applications, needle valves play a critical role in flow control, often requiring meticulous attention during installation and maintenance to ensure optimal performance. According to a report by the Flow Control Products Association, improperly installed or maintained valves can lead to a significant increase in system failures, sometimes up to 30% more operational downtime. To mitigate these risks, it is crucial to adhere to best practices during the installation process. Proper torque specifications and alignment must be followed to prevent leaks and ensure the longevity of the valve.

Tip: Before installation, always inspect the needle valve for any signs of damage or wear. Ensuring all threads and seating surfaces are clean can prevent issues later on.

Regular maintenance is just as essential, with experts recommending that facilities perform routine inspections every six months. This includes checking for corrosion, ensuring seals are intact, and confirming that the valve operates smoothly. Consistent monitoring can help identify potential issues before they escalate. Furthermore, the American Society of Mechanical Engineers suggests documenting maintenance activities to maintain a comprehensive history, contributing to better decision-making for future valve replacements or upgrades.

Tip: Keep an inventory of spare parts for needle valves. This can significantly reduce downtime during unexpected failures, enabling quicker repairs and maintaining productivity in your operations.

Related Posts

-

10 Best Needle Valves for Precision Control in Fluid Systems

-

Exploring the Innovative Applications of Tube Fittings in Modern Engineering Solutions

-

Why High Pressure Fittings Are Essential for Safe Industrial Applications

-

Why Choosing the Right AN Hose Fittings is Essential for Your Performance Upgrades

-

Why Tubing Connectors are Essential for Optimal Fluid Management Systems

-

10 Best Fuel Fittings for Optimal Engine Performance in 2023