- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

How to Choose the Right Pressure Fittings for Your Plumbing Needs

Choosing the right pressure fittings for your plumbing needs is crucial for ensuring efficiency and safety in any system. As industry expert John Smith, a certified plumbing engineer, notes, "The right pressure fittings can make or break the integrity of your plumbing installation." With various materials, sizes, and designs available, the selection process can become overwhelming for both homeowners and professionals alike.

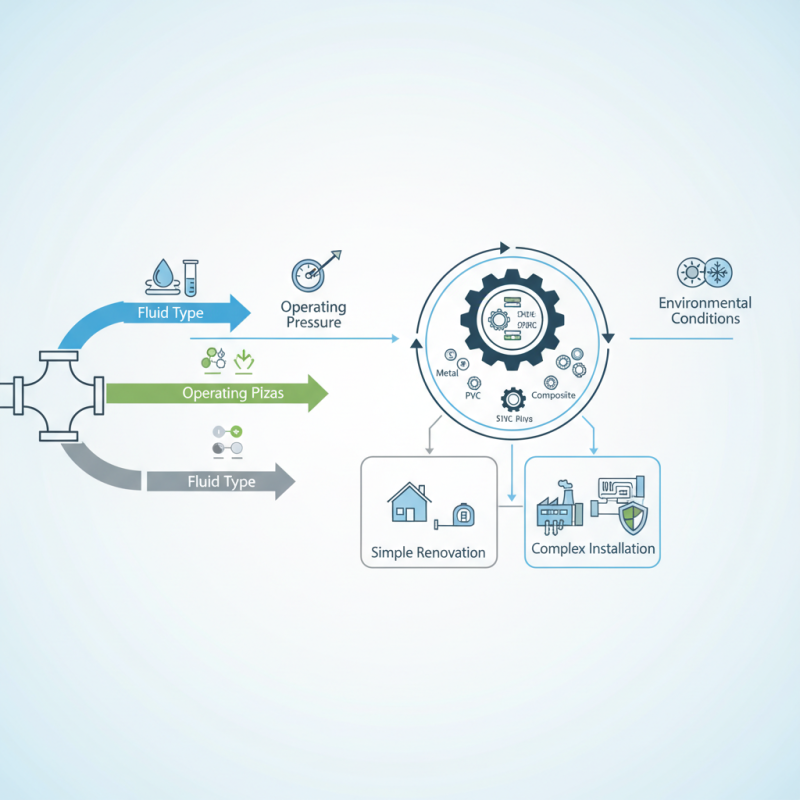

Understanding the specific requirements of your plumbing project is essential when navigating through the myriad of options. Factors such as the type of fluid being transported, the operating pressure, and environmental conditions play a significant role in determining which pressure fittings are best suited for your application. A thoughtful approach to choosing these components can lead to enhanced performance and longevity of your plumbing system.

In this guide, we will explore the key considerations for selecting the right pressure fittings, ensuring you are equipped with the knowledge to make informed decisions. Whether you are tackling a simple renovation or a complex installation, the right pressure fittings are paramount for achieving optimal results.

Understanding Different Types of Pressure Fittings in Plumbing

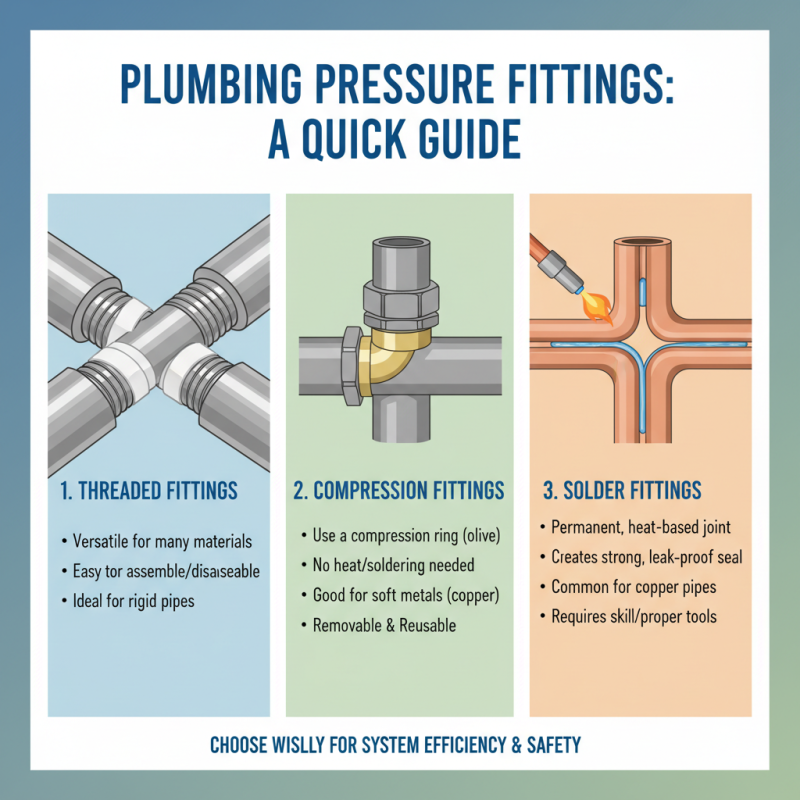

When it comes to plumbing, selecting the right types of pressure fittings is crucial for ensuring the efficiency and safety of your system. Pressure fittings are designed to connect various pipes and components while withstanding high pressures without leaking. The most common types of pressure fittings include threaded fittings, compression fittings, and solder fittings. Each type has its own unique advantages, making them suitable for different applications and environments.

Threaded fittings are ideal for pipe connections that may need to be disassembled in the future, as they allow for easy installation and maintenance. They come in various materials, such as metal and plastic, providing versatility depending on the required pressure rating and type of fluid being transported. Compression fittings, on the other hand, create a secure seal by compressing a ring onto the pipe when tightened. This type is particularly useful in situations where movement or vibrations might occur, as they maintain integrity under stress. Lastly, solder fittings are typically used in copper pipe systems and provide a permanent connection by melting solder to bond the fitting and the pipe, offering durability for long-term installations.

Understanding the specific requirements of your plumbing project, including pressure ratings, fluid types, and environmental conditions, can guide you in selecting the right pressure fittings. Each fitting type serves distinct purposes and thrives in varying applications, which can ultimately impact the performance and longevity of your plumbing system.

Evaluating Material Compatibility for Pressure Fittings

When selecting pressure fittings for plumbing applications, evaluating material compatibility is crucial to ensure system reliability and performance. According to a report from the International Association of Plumbing and Mechanical Officials (IAPMO), improper material pairing can lead to premature failure, leaks, or even catastrophic system breakdowns. For instance, copper and PVC cannot be used together in high-pressure environments due to their differing thermal expansion rates and chemical resistance properties. This can result in joint failures that compromise the integrity of the entire plumbing system.

Different materials exhibit unique characteristics that affect their suitability for various conditions. Stainless steel fittings, for example, offer excellent resistance to corrosion and are typically favored in high-stakes environments, such as hospitals or pharmaceutical facilities, where sanitary conditions are paramount. A study from the American Society of Mechanical Engineers (ASME) indicates that stainless steel can withstand temperatures up to 1,600°F, making it suitable for both high-temperature and high-pressure applications. In contrast, thermoplastic fittings may be more appropriate for corrosive fluids but may not hold up under extreme temperature fluctuations. Understanding these material properties is essential for selecting the right pressure fittings that fit the specific needs of your plumbing project.

Assessing Pressure Ratings and Their Importance in Selection

When selecting pressure fittings for plumbing systems, understanding pressure ratings is essential. These ratings indicate the maximum pressure a fitting can handle safely and are crucial for ensuring the integrity and longevity of your plumbing installation. Higher pressure ratings often mean increased material strength, which can be vital in instances where your plumbing system may experience fluctuations in pressure. Always consult the specifications of your plumbing system to identify the suitable pressure ratings for your fittings.

Tips: Before purchasing, check the specifications of your water source to determine the maximum expected pressure. Additionally, consider the environment where the fittings will be installed—temperature and exposure to other factors can influence performance.

It’s also important to recognize that not all applications require the same pressure ratings. For example, residential plumbing systems typically have lower pressure requirements than industrial applications. In such cases, excessive pressure fittings can not only be overkill but may lead to other issues like leaks or installation complications. Always align the pressure rating with your particular needs to strike the right balance between safety and efficiency.

Tips: When in doubt, consult with a plumbing professional to assess your specific needs based on your system's pressure demands and environmental factors. Having the right fittings can save time and money in the long run.

Considering Pipe Size and Connection Types for Optimal Fit

When selecting pressure fittings for plumbing, understanding pipe size and connection types is crucial for ensuring an optimal fit. The size of your pipes will dictate the measurements needed for fittings, as different plumbing systems may use varying dimensions. Accurate measurement, including both the diameter and wall thickness of the pipes, will help in finding the right fittings that create a secure and efficient flow of fluid.

Tip: Always double-check the size specifications of your pipe and fittings before making a purchase. Using a caliper or measuring tape can provide precise dimensions, which help avoid compatibility issues during installation.

In addition to pipe size, the type of connection plays a vital role in determining the best pressure fittings. Common connection types include threaded, soldered, and push-fit. Each type may require specific skills and tools for installation, so knowing which connection method works best for your plumbing situation can save time and resources.

Tip: Consider the long-term maintenance of your plumbing system. Some connection types can facilitate easier disassembly and repairs, while others may provide a more permanent solution. Always weigh the pros and cons of connection types in relation to your specific needs.

Common Mistakes to Avoid When Choosing Pressure Fittings

When selecting pressure fittings for plumbing needs, one of the most common mistakes is underestimating the importance of compatibility with existing plumbing materials. According to a report by the American Society of Plumbing Engineers, improper matching of fittings can lead to leaks and system failures, with estimated repair costs potentially exceeding $1,000. It's crucial to consider factors such as material type—whether it's copper, PVC, or stainless steel—and ensure that the pressure fitting is designed to work seamlessly with these materials to maintain system integrity.

Another frequent error is overlooking the specifications required for the application, including pressure ratings and temperature tolerances. The Plumbing and Mechanical Institute notes that using fittings that are not rated for the specific pressure conditions can cause catastrophic failures. For instance, fittings designed for low-pressure systems might burst under high-pressure circumstances. Thus, thoroughly reviewing the required specifications and ensuring the chosen fittings meet or exceed these standards is essential for the longevity and reliability of the plumbing system.

Related Posts

-

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

-

Why High Pressure Fittings Are Essential for Safe Industrial Applications

-

How to Choose the Right Pipe Plug for Your Plumbing Needs

-

Essential Plumbing Fittings Every DIY Enthusiast Should Know About

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project