- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

How to Choose the Right Quick Connectors for Your Projects?

In various industries, quick connectors play a crucial role in enhancing efficiency and safety in fluid transfer systems. According to a recent report by MarketsandMarkets, the global quick connectors market is expected to reach USD 6.2 billion by 2026, highlighting their increasing application across sectors like automotive, aerospace, and agriculture. These connectors not only streamline operations but also reduce the risk of leaks and spills, which can lead to significant financial losses and environmental hazards.

When selecting quick connectors for projects, several factors come into play. Compatibility with fluid types, pressure ratings, and temperature ranges are vital considerations. For instance, choosing a connector made from materials resistant to corrosion can prolong longevity and reliability. However, despite numerous options available, many professionals still struggle to identify the right type for their specific needs. This shows a gap that can lead to costly mistakes and inefficiencies in operations.

Understanding the diverse types of quick connectors on the market can be daunting. Many choices are available, but without proper knowledge, one might end up with inadequate solutions. It’s essential to invest time in research and seek expert advice when necessary. Missteps in choosing quick connectors can hinder performance and impact project success.

Understanding Quick Connectors: Types and Applications

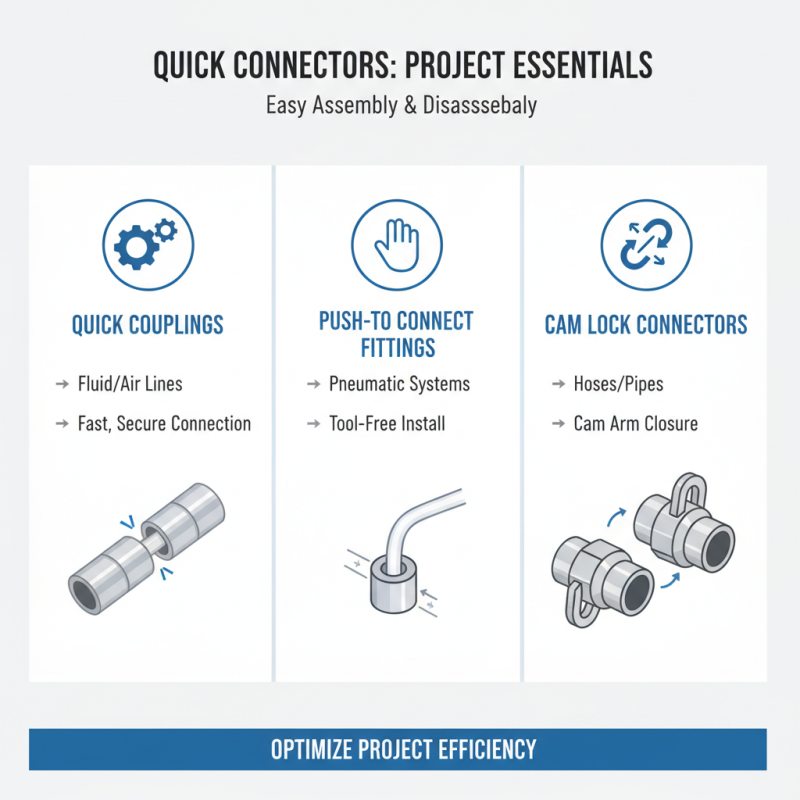

Quick connectors are essential tools in many projects, facilitating easy assembly and disassembly. These connectors come in various types, each suited for different applications. Common types include quick couplings, push-to-connect fittings, and cam lock connectors. Each type serves a unique purpose, influencing your project's efficiency and effectiveness.

Understanding the specific applications of each connector type is crucial. Quick couplings, for instance, excel in hydraulic systems requiring fast fluid transfers. Push-to-connect fittings are popular for air and water lines, providing a secure yet easy connection. Cam lock connectors are often used in construction and agricultural settings. They allow for rapid setup and breakdown of operations. Yet, many users overlook the compatibility and pressure ratings, leading to mismatched connections.

Assessing the right quick connector can be challenging. Not all connectors will fit every project. Misjudging the required type may hinder performance. It's worth reflecting on previous choices, understanding the needs of your specific application, and ensuring the right fit. In the end, the right choice enhances not just functionality but also safety and reliability in your work.

Assessing Project Requirements for Quick Connectors Selection

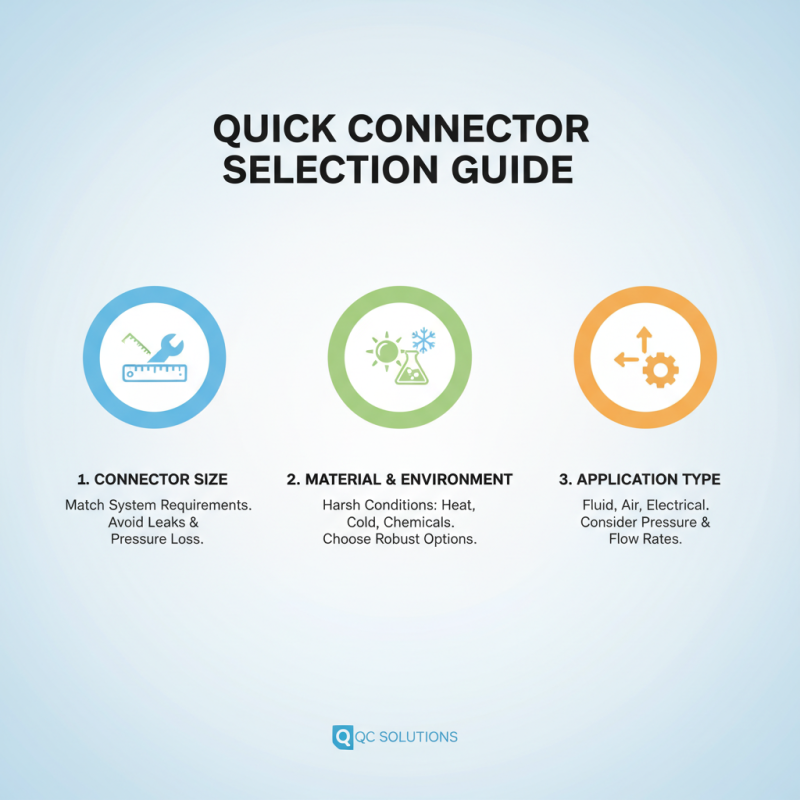

When selecting quick connectors for your projects, you must assess your requirements carefully. Consider the application environment first. Is it exposed to high temperatures or moisture? The material of the connector should be resistant to these conditions. Think about the fluid types as well. Various connectors are designed for specific media, and using the wrong one can cause leaks.

One important tip is to consider the connector's pressure rating. Ensure it matches your system's pressure levels. Many connectors are tested for durability, but not all withstand extreme conditions. Don't overlook dimensions either. An ill-fitting connector can lead to inefficiency and require costly adjustments later.

Always evaluate the connection method. Some quick connectors use simple push-to-connect designs, while others require tools for assembly. Your project timeline may influence this choice. Simpler connections may speed things up but may compromise reliability if not chosen carefully. Reflect on your project's specifics before making a decision; avoid assumptions that could lead to errors in the field.

Quick Connectors Selection Criteria

Key Specifications to Consider When Choosing Quick Connectors

When selecting quick connectors for your projects, several key specifications should influence your decision. The size of the connector is crucial. It needs to match the system's requirements. A mismatch can lead to leaks or pressure losses, causing inefficiencies. Think about the environment too. Connectors in harsh conditions need robust materials. Choose options that withstand heat, cold, or chemicals.

Another important factor is the flow rate. Each connector type has a specific flow capacity. Ensure it meets your project’s needs. A connector with a low flow rate may slow down your system. Meanwhile, excessive flow can cause turbulence or damage components. Pay attention to the coupling mechanism as well. Some designs are easier to operate. A user-friendly connector can prevent frustration and errors during assembly.

Lastly, consider maintenance and replacement aspects. Not all connectors are easy to service. Some may require special tools for disconnection. Frequent projects might benefit from connectors that allow easy access. Reflect on your project's longevity too. Temporary solutions may not suffice in long-term setups. Finding the right balance among these specifications takes time and careful thought.

Evaluating Material Compatibility for Quick Connectors

Choosing the right materials for quick connectors is vital. Compatibility can influence durability and performance. A 2021 industry report from the Fluid Power Society notes that improper material choices lead to 30% of connector failures. This highlights the necessity for thorough evaluation before making a selection.

Common materials include metal, plastic, and rubber. Metals like stainless steel resist corrosion, while plastics are lightweight and cost-effective. However, not all plastics withstand high temperatures or aggressive chemicals. For example, polycarbonate may degrade under UV exposure. Rubber seals often provide a tight fit but can deteriorate more quickly in harsh environments.

Conducting tests is crucial. Check how your connectors hold up in specific conditions. Data from the Industrial Standards Organization reveals that connectors failing to meet compatibility standards can result in significant downtime, costing companies thousands. Consider real-world environments during this process. Balancing performance with cost may require compromises, but ignoring material compatibility is a recipe for failure.

Installation and Maintenance Tips for Quick Connectors

When installing quick connectors, it's crucial to ensure a snug fit. Check the compatibility with your hoses and equipment. A mismatch can lead to leaks. Always clean the connection points before installation. Dirt or debris can compromise the seal. This step saves you from future troubles.

Routine maintenance is equally important. Inspect connectors regularly for wear and tear. Look for cracks or discoloration that signal degradation. Sometimes, a simple tightening can prevent problems. Don’t ignore minor leaks; they can escalate quickly. Replace seals as needed. Over time, they can become brittle and lose effectiveness.

Consider the environment where the connectors will be used. High temperatures can affect performance. Humidity might cause corrosion. Ensure materials used are suitable for your specific application. Remember, neglecting these details can lead to inefficiencies. Always take time to review and reflect on performance. It may not be perfect, but improvement comes with practice.

How to Choose the Right Quick Connectors for Your Projects? - Installation and Maintenance Tips for Quick Connectors

| Connector Type | Material | Pressure Rating | Temperature Range | Application | Maintenance Tips |

|---|---|---|---|---|---|

| Push-to-Connect | Polymer | 150 psi | -20°C to 80°C | Air, Water | Regularly inspect for wear and tear. |

| Threaded Connectors | Brass | 300 psi | -50°C to 150°C | Gas, Oil | Use on/off seals to prevent leaks. |

| Quick Couplers | Aluminum | 250 psi | -20°C to 100°C | Hydraulic Systems | Check seals and O-rings for degradation. |

| Barbed Connectors | PVC | 120 psi | 0°C to 60°C | Water Transfer | Ensure a secure fit to avoid leaks. |

| Cam and Groove | Stainless Steel | 500 psi | -40°C to 200°C | Chemical Transfer | Clean fittings after each use. |

Related Posts

-

Exploring Quick Connectors: The Unsung Heroes of Efficient Plumbing and Wiring Solutions

-

Why Tubing Connectors are Essential for Optimal Fluid Management Systems

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

How to Choose the Right Needle Valves for Your Industrial Applications

-

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

-

10 Best Fuel Fittings for Optimal Engine Performance in 2023