- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

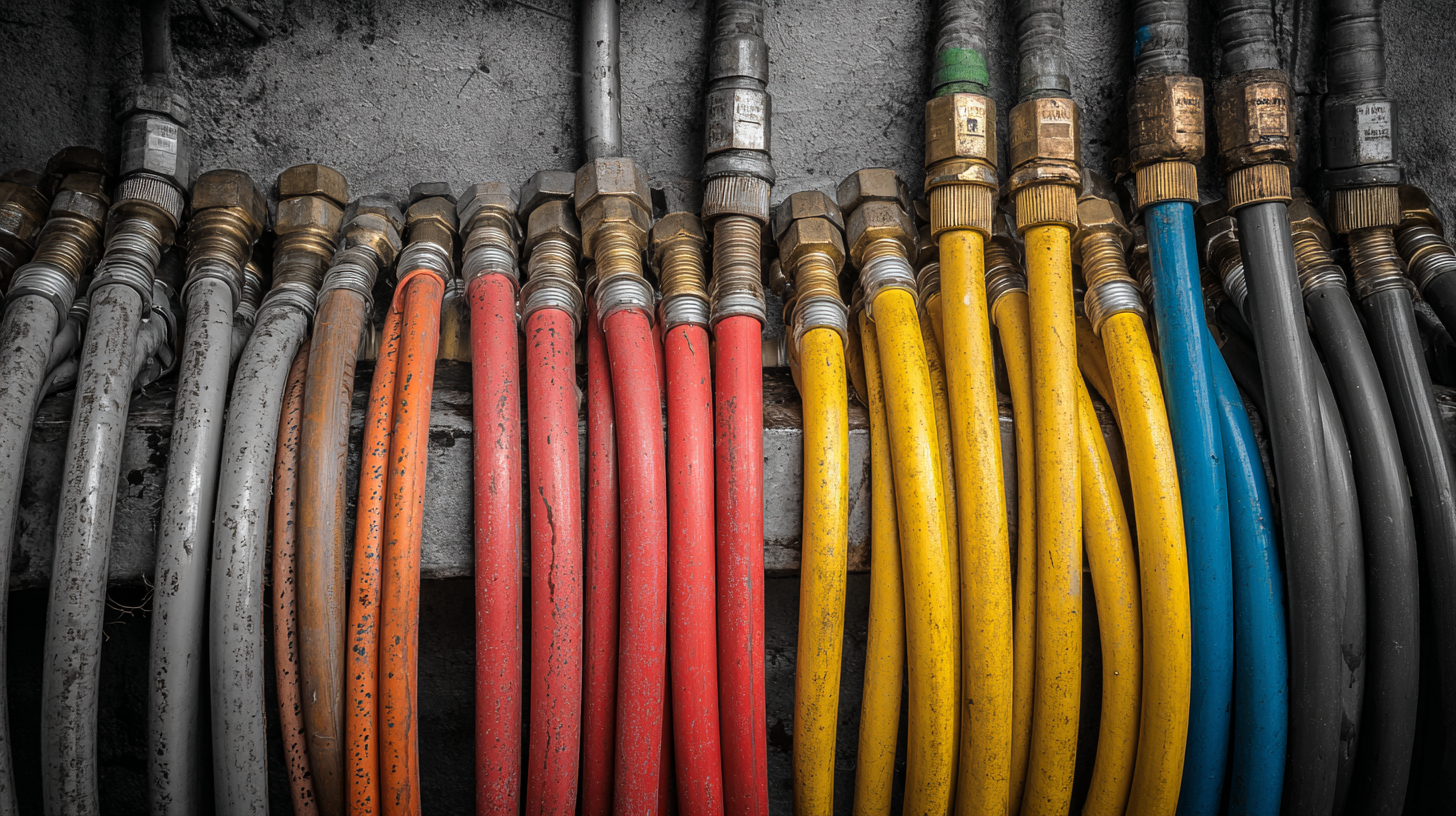

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

In today's rapidly evolving industrial landscape, the selection of the appropriate hose and fittings is paramount to ensuring operational efficiency and safety in various projects. According to a report by the Fluid Power Journal, about 20% of hydraulic system failures can be attributed to improper hose and fittings choices, resulting in significant downtime and repair costs. Additionally, a study from the National Institute for Safety and Health indicates that the right hose and fittings can enhance fluid handling capabilities, contributing to overall system effectiveness by up to 30%. With such critical implications for productivity and safety, understanding the essential factors in choosing the right hose and fittings is crucial for engineers, technicians, and project managers alike. This guide aims to equip you with the knowledge needed to make informed decisions tailored to your specific project requirements.

Understanding Different Hose Types: Materials and Applications

When selecting hoses for your project, it's essential to understand the different types available, each with unique materials and applications. Common hose materials include PVC, rubber, and polyurethane, each offering distinct advantages. For instance, PVC hoses are lightweight and resistant to weathering, making them ideal for irrigation and light-duty applications. According to the Flexible Hose and Tubing Market report by Grand View Research, the global market for hoses and tubing was valued at over $10 billion in 2023, indicating a robust demand driven by diverse industries.

Tips: Always consider the working pressure and temperature of your application when choosing a hose. Rubber hoses, known for their durability and flexibility, are perfect for heavy-duty tasks, such as construction and landscaping. On the other hand, polyurethane hoses are renowned for their chemical resistance and are suitable for industrial applications, particularly in environments with harsh substances.

Additionally, understanding the fitting types is crucial. Depending on the hose type, standard or quick-connect fittings may be necessary. The right connector ensures leak-free performance and helps maintain the efficiency of your system. Remember to check compatibility between hoses and fittings to optimize your project’s success.

Key Considerations for Selecting Hose Fittings: Size, Compatibility, and Pressure Ratings

When selecting hose fittings for your project, size is one of the most critical factors to consider. The diameter of the hose must match the fittings precisely to ensure a secure and leak-free connection. Using fittings that are too large or too small can lead to reduced efficiency, increased wear, and potential failure of the system. Therefore, it is essential to measure both the hose and the fittings accurately before making a purchase. Standard sizes are often available, but custom options can also be tailored to meet specific requirements.

When selecting hose fittings for your project, size is one of the most critical factors to consider. The diameter of the hose must match the fittings precisely to ensure a secure and leak-free connection. Using fittings that are too large or too small can lead to reduced efficiency, increased wear, and potential failure of the system. Therefore, it is essential to measure both the hose and the fittings accurately before making a purchase. Standard sizes are often available, but custom options can also be tailored to meet specific requirements.

Compatibility is another key consideration. Different materials and design types exist for hoses and fittings, including plastic, rubber, and metal varieties. It's important to ensure that the materials are compatible with the fluids they will transport, as certain combinations can lead to degradation or failure over time. Additionally, check for specific coupling types, as some hoses and fittings may have unique connections. Finally, pressure ratings must be thoroughly reviewed, as using a fitting with a lower pressure rating than the hose can result in catastrophic failures. Always choose fittings that meet or exceed the maximum pressure your project will encounter to maintain safety and effectiveness.

Industry Standards and Certifications: Ensuring Quality in Hoses and Fittings

When selecting hoses and fittings for any project, it’s crucial to understand the industry standards and certifications that ensure product quality and reliability. Various organizations, such as the American National Standards Institute (ANSI) and the American Society for Testing and Materials (ASTM), set specific guidelines that manufacturers must adhere to when producing hoses and fittings. Compliance with these standards not only guarantees that the products can withstand the required pressure and temperature but also assures users of their safety and performance.

In addition to ANSI and ASTM, certifications from entities like the National Sanitation Foundation (NSF) and Underwriters Laboratories (UL) provide an extra layer of assurance regarding health and safety. NSF certification indicates that a product meets public health and safety standards, while UL certification signifies that the equipment has undergone rigorous testing for safety. Choosing hoses and fittings that bear these marks of quality helps safeguard your project from potential failures and enhances overall efficiency, making the selection process much more secure and informed.

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

Calculating Flow Rates: Matching Hose Diameter with Project Requirements

When embarking on a project that requires specific hose and fitting choices, understanding the interaction between hose diameter and flow rates is crucial. A properly selected hose diameter can optimize fluid dynamics, ensuring effective delivery and reducing pressure loss.

According to recent research on hydraulic hoses, the length of a hose can significantly influence dynamic pressure waveforms, which are critical for applications where precise flow control is necessary. For instance, varying the length of steel hoses produced different frequency responses, affecting overall performance in hydraulic systems.

When calculating the required flow rates for your project, consider the size and length of your hoses. A larger diameter can facilitate a higher flow rate; however, if the hose is too wide for the application, it may lead to stagnation and inefficient flow. As a practical tip, always perform calculations based on the expected flow conditions—taking into account factors like pressure drops and hose length.

Moreover, ensure that your hose selection aligns with your flow requirements. For applications needing constant flow rates, specialized equipment like peristaltic pumps can maintain the desired output efficiently. Remember, a well-matched hose diameter not only enhances performance but also improves the reliability and longevity of your system.

Maintenance Tips and Best Practices for Longevity of Hoses and Fittings

When selecting hoses and fittings for your project, understanding maintenance tips and best practices is crucial for ensuring longevity. One of the most common issues homeowners face is kinking, which can damage the hose and impede water flow. To mitigate this, always choose a hose made from high-quality materials and avoid sharp bends during storage. Additionally, consider the appropriate diameter for your needs—too wide or too narrow can affect performance.

Regular inspection is essential. Routinely check for leaks, wear, or cracks, especially at connection points. Cleaning the hoses after use keeps them in optimum condition; simply drain and store them without any water left inside. Utilizing protective covers can also shield hoses from UV exposure and prolong their lifespan. By being proactive with maintenance and choosing the right products, you’ll ensure smooth, hassle-free operation for years to come.

Related Posts

-

Innovative Applications for Tubing Connectors in Modern Industries

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

Maximizing Efficiency: The Future of Hose Fittings in Industrial Applications

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency