- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

How to Choose the Right Tube Fittings for Your Plumbing Projects

Choosing the right tube fittings is a crucial aspect of any plumbing project, whether you are a seasoned professional or a DIY enthusiast. Tube fittings serve as essential connectors that join various segments of piping systems, ensuring both efficiency and safety in fluid transport. With the myriad of options available on the market, it can be overwhelming to determine which type of tube fitting best suits your specific needs.

In this guide, we will explore the factors to consider when selecting tube fittings, such as material compatibility, pressure ratings, and application requirements. Understanding these key elements will help you make informed decisions that enhance the overall performance and longevity of your plumbing systems. Furthermore, we will discuss the significance of proper installation techniques, which play a vital role in preventing leaks and ensuring the reliability of your setup. By focusing on these aspects, you'll be well-equipped to choose the right tube fittings for your plumbing projects, ultimately achieving a successful outcome.

Understanding Different Types of Tube Fittings Available in the Market

When selecting tube fittings for plumbing projects, understanding the various types available in the market is crucial to ensuring optimal performance and durability. Tube fittings primarily fall into several categories, including compression fittings, flare fittings, and push-to-connect fittings. According to the Fluid Power and Motion Control market report, the use of compression fittings is favored in applications requiring high pressure and leak-free connections, making them a prevalent choice in both residential and commercial plumbing.

When considering which type of tube fitting to use, it’s essential to evaluate the material compatibility with the intended application. For instance, stainless steel fittings provide excellent resistance to corrosion, making them suitable for both hot and cold water service, while plastic fittings may be adequate for less demanding environments like irrigation systems. The global market for tube fittings is projected to reach $3 billion by 2027, underscoring the importance of choosing high-quality fittings that can withstand varying pressures and temperatures.

Tips: Before purchasing, always verify the specifications of your selected fittings to ensure they match the requirements of your pipes. Additionally, consider the ease of installation; push-to-connect fittings are often preferred for DIY projects due to their straightforward assembly without the need for specialized tools. Lastly, always check for certification marks that indicate compliance with industry standards to ensure your plumbing systems function safely and efficiently.

Tube Fittings Types and Their Common Applications

This bar chart displays various types of tube fittings commonly used in plumbing projects, along with their respective applications. Understanding these fittings helps in selecting the right one for your specific needs.

Identifying the Material Compatibility for Your Plumbing Needs

When selecting tube fittings for your plumbing projects, identifying material compatibility is crucial to ensuring long-lasting performance and preventing costly leaks. Different plumbing systems utilize various materials, such as copper, PVC, stainless steel, and PEX, each with unique properties and suitable applications. For example, a report by the Plumbing Manufacturers International indicates that copper fittings are ideal for high-pressure applications due to their excellent durability and resistance to corrosion, while PVC is favored for lower-pressure systems and its ease of installation.

Tips: Always check the manufacturer's specifications regarding temperature and pressure ratings for each type of fitting. Consider the environment where the plumbing will be utilized; for outdoor settings, for instance, UV-resistant materials might be necessary to prevent degradation.

Another critical factor is the compatibility of the fittings with the fluids being transported. According to the American Society of Plumbing Engineers, certain materials can interact negatively with particular fluids, leading to degradation or failure. For instance, using brass fittings with highly acidic fluids can lead to corrosion. It’s essential to consult chemical compatibility tables to ensure that the chosen materials will withstand the substances they will encounter.

Tips: Whenever possible, conduct a compatibility test with a sample before implementing a larger installation. This can save time and resources by identifying potential issues early in the process.

| Material Type | Temperature Range (°C) | Pressure Rating (psi) | pH Compatibility | Common Applications |

|---|---|---|---|---|

| Copper | -40 to 100 | 300 | 6 - 8 | Water Supply, HVAC |

| PVC | 0 to 60 | 200 | 4 - 9 | Drainage, Waste, Vent |

| Stainless Steel | -50 to 450 | 1500 | 1 - 14 | Food Processing, Chemical Handling |

| Brass | -20 to 93 | 600 | 6 - 8 | Plumbing, Hydraulics |

| PEX | -40 to 95 | 160 | 6 - 8 | Hot and Cold Water Supply |

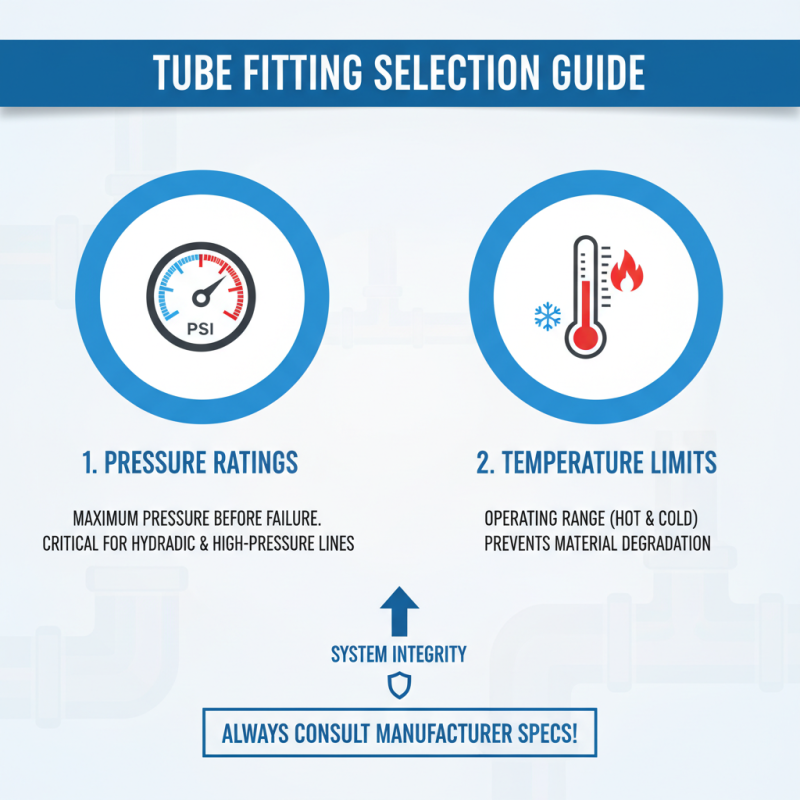

Evaluating Pressure Ratings and Temperature Limits of Tube Fittings

When choosing the right tube fittings for your plumbing projects, two critical factors to consider are the pressure ratings and temperature limits of the fittings. Pressure ratings indicate the maximum pressure a fitting can withstand without failure, which is essential for maintaining system integrity. Higher pressure applications, such as in hydraulic systems or high-pressure water lines, require fittings that are rated to handle these conditions safely. It's crucial to consult the specifications provided by manufacturers to ensure that the chosen fittings meet the demands of your specific application.

Similarly, temperature limits play a vital role in the selection of tube fittings. Fittings often have a defined temperature range within which they can operate effectively without compromising their structural integrity or causing leaks. For applications involving hot water or steam, it is essential to select materials that can endure elevated temperatures without degrading. Understanding the operational environment, including any potential temperature fluctuations, will help ensure the longevity and reliability of your plumbing system. Overall, a careful evaluation of both pressure ratings and temperature limits will guide you in making an informed choice that meets the needs of your project.

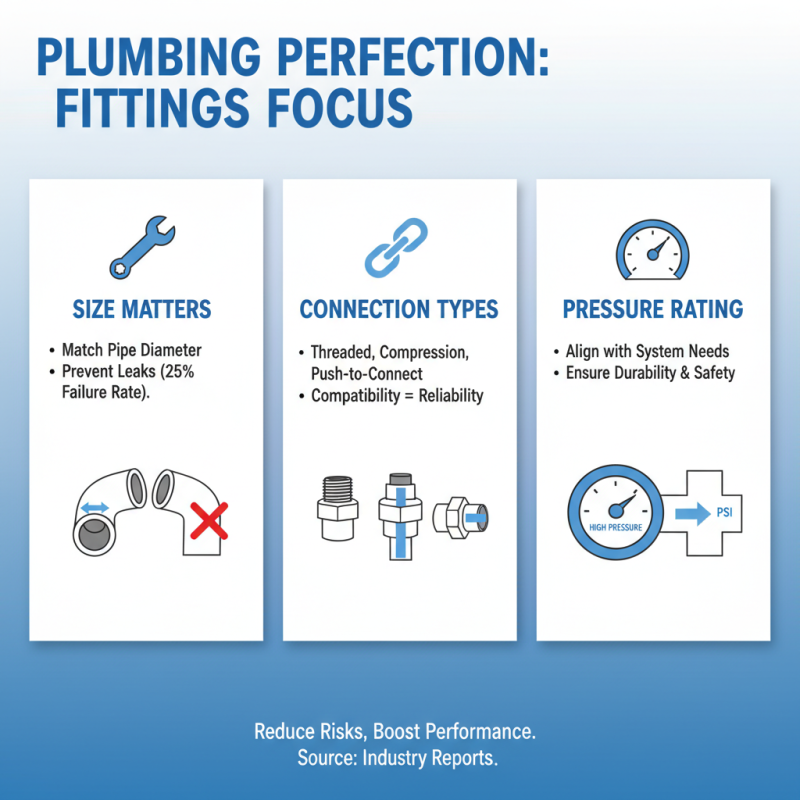

Selecting the Correct Size and Connection Types for Your Project

When selecting the appropriate tube fittings for plumbing projects, it is crucial to focus on the correct size and connection types. According to industry reports, approximately 25% of plumbing failures can be attributed to improperly sized or incompatible fittings. Ensuring that the fittings align with the diameter of the pipes, as well as the intended pressure ratings, can significantly reduce the risk of leaks and failures.

One key aspect to consider is the material compatibility between the tube fittings and pipes. For instance, using brass fittings with copper or plastic pipes can yield different thermal expansion and contraction rates, leading to potential failures over time. Industry data suggests that using mismatched materials can decrease the lifespan of plumbing systems by as much as 30%.

Tips: Always measure the internal and external diameters of your pipes and refer to manufacturer specifications to ensure compatibility. Additionally, consider the type of connection—such as compression, soldered, or threaded—as each has its own advantages depending on the application. Remember that accurate installation can enhance the overall performance of your plumbing setup, making the right choices critical for any project.

Tips for Installation and Maintenance of Tube Fittings in Plumbing Systems

When installing tube fittings in plumbing systems, it is essential to ensure a

tight and leak-free connection. Begin by selecting the appropriate type of fitting for your specific application, considering factors such as the pipe material and the pressure requirements of the system.

Thoroughly clean the ends of the tubes and fittings before assembly to remove any debris or contaminants. This preparation is critical as it helps achieve a proper seal and prevents premature failure of the connection.

During installation, always follow the recommended torque specifications to avoid damaging the fittings or the pipe. Over-tightening can lead to cracks, while under-tightening may result in leaks. Employing a torque wrench can provide better accuracy. Additionally, use thread sealants and plumbers' tape where appropriate, but be cautious not to overapply, as this can also hinder the effectiveness of the seal. After assembly, conduct a pressure test to identify any leaks and ensure all connections are secure before putting the system into operation.

Regular maintenance of tube fittings is also vital. Periodically inspect fittings for signs of wear, corrosion, or leaks, especially in high-pressure systems. If any issues are detected, address them immediately to prevent larger problems down the line. Keeping the fittings clean and free from debris will also contribute to their longevity. By adhering to proper installation and maintenance practices, you can significantly enhance the performance and reliability of your plumbing systems.

Related Posts

-

Exploring the Innovative Applications of Tube Fittings in Modern Engineering Solutions

-

10 Essential Tips for Choosing the Right Tube Fittings for Your Projects

-

Why Tube Fittings Are Essential for 70% of Industrial Fluid Systems Efficiency

-

How to Choose the Right Needle Valves for Your Industrial Applications

-

10 Best Needle Valves for Precision Control in Fluid Systems

-

Top 10 Essential Plumbing Fittings Every Homeowner Should Know About