- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

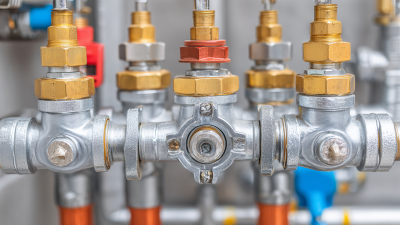

Understanding the Importance of Ball Valves in Modern Industrial Applications

In modern industrial applications, the efficiency and reliability of fluid control systems are paramount. Among the various components that facilitate these systems, ball valves stand out as essential devices for managing the flow of liquids and gases. Their unique design, which employs a spherical disc to control the flow, offers several advantages that make them indispensable in diverse industries, from oil and gas to pharmaceuticals and water treatment. Understanding the importance of ball valves not only enhances operational efficiency but also contributes to safety and sustainability in industrial processes.

This article delves into the critical role of ball valves in contemporary settings, highlighting their functions, benefits, and best practices for selection and maintenance. By employing a digital approach, we will provide valuable insights, tips, and guidelines on how to leverage ball valves effectively. Readers will gain a comprehensive understanding of why these components are a cornerstone of modern industrial applications, as well as practical advice on optimizing their use to ensure seamless operations and reduced downtime. Through this exploration, the significance of incorporating high-quality ball valves into your fluid management systems will be made abundantly clear.

How to Select the Right Ball Valve for Your Industrial Needs

In modern industrial applications, the selection of the right ball valve is crucial for ensuring operational efficiency and safety. Ball valves play a significant role in various sectors, including oil and gas, pharmaceuticals, and renewable energy, where precise control of fluid flow is vital. According to industry reports, improperly chosen valves can lead to significant financial losses and jeopardize system integrity, highlighting the need for careful consideration when selecting these components.

When selecting a ball valve, it’s essential to consider factors such as material compatibility, pressure and temperature ratings, and the type of flow required. For instance, materials such as stainless steel and brass are often favored for their durability and resistance to corrosion. Additionally, choosing the correct valve size is critical; a valve that is too large or small can affect flow rates and overall system performance.

**Tips:**

- Always consult manufacturer specifications to ensure you are matching the valve type to the intended application.

- Consider future maintenance and replacement needs when selecting a valve, as accessibility can affect ongoing operational costs.

Making informed choices based on comprehensive research and reliable industry insights will not only enhance system performance but also contribute to long-term operational success.

How to Ensure Proper Installation and Maintenance of Ball Valves

Proper installation and maintenance of ball valves are crucial for ensuring their optimal performance in industrial applications. To begin with, when installing a ball valve, it is essential to verify that all components are clean and free from debris. The correct alignment of the valve within the piping system is also vital to prevent any stress on the valve body, which can lead to premature failure. Utilizing appropriate gaskets and seals during installation helps to ensure a tight fit, preventing leaks that could disrupt operations.

In terms of maintenance, regular inspections should be scheduled to check for signs of wear, corrosion, or any operational issues. Lubricating the valve mechanism can enhance performance and facilitate easier operation, particularly in high-frequency use scenarios. Additionally, conducting periodic testing of the valve’s functionality ensures that it remains responsive and reliable in regulating flow. By adhering to these installation and maintenance practices, industries can maximize the lifespan and efficiency of their ball valves, avoiding costly downtimes and repairs.

How to Troubleshoot Common Issues with Ball Valves in Operations

In industrial operations, ball valves play a crucial role due to their reliability and efficiency in controlling the flow of fluids. However, like any mechanical component, they can encounter problems that may disrupt operations. Troubleshooting common issues with ball valves is essential for maintaining seamless industrial processes. For instance, if a ball valve fails to open or close properly, it could indicate issues such as debris lodged in the valve or damage to the sealing surfaces. Regular inspection and maintenance can help identify these problems before they escalate.

Another frequent issue is leakage, which can arise from wear and tear or improper installation. Operators should check the valve for signs of leakage around the stem or body and ensure that the valve is installed according to the manufacturer's specifications. Additionally, ensuring that the valve operates within its specified pressure and temperature ranges can prevent many operational failures. By understanding and addressing these common issues, industries can significantly enhance the longevity and performance of ball valves, ensuring efficient and safe operations.

How to Optimize Performance and Efficiency with Ball Valves

Ball valves are increasingly recognized for their critical role in various industrial applications, thanks to their ability to provide reliable flow control. Optimizing the performance and efficiency of these valves is essential for enhancing operational capabilities. According to a report by the International Society of Automation, ball valves can achieve flow coefficients (Cv) 30% higher than traditional gate valves, allowing for reduced energy consumption and improved overall efficiency.

To maximize the benefits of ball valves, it’s crucial to focus on proper sizing and selection. Over 60% of industrial operations report that improper valve sizing leads to increased maintenance costs and downtime. Using advanced software tools for valve sizing can ensure that the chosen ball valve matches the specific flow requirements of the application, significantly reducing operational inefficiencies. Additionally, regular maintenance practices, such as lubricating the valve seats and monitoring for wear, can lead to a 20% increase in the lifespan of the valves, ultimately resulting in lower total cost of ownership.

Additionally, integrating smart technology with ball valves can further optimize their performance. Reports indicate that facilities implementing IoT-enabled valves see a 25% reduction in unplanned outages, as real-time monitoring allows for predictive maintenance. This proactive approach not only enhances the reliability of operations but also fosters a culture of continuous improvement, paving the way for more sustainable industrial practices.

Performance and Efficiency of Ball Valves in Industrial Applications

How to Compare Different Materials and Designs for Ball Valves in Industry

When comparing different materials and designs for ball valves in industrial applications, it's crucial to consider factors such as durability, resistance to corrosive substances, and cost-effectiveness. According to a recent report by the Global Ball Valves Market Research, the demand for stainless steel ball valves is projected to grow significantly, driven by their excellent corrosion resistance and mechanical strength, essential in industries like oil and gas and petrochemical processing. Specifically, stainless steel valves are noted for their ability to withstand high pressures and temperatures, making them ideal for demanding environments.

In addition to materials, the design of ball valves also plays a pivotal role in their effectiveness. The industry is increasingly favoring designs that facilitate easier maintenance and enhanced flow characteristics, such as trunnion-mounted ball valves. According to a study by the American Society of Mechanical Engineers, trunnion-mounted designs reduce the torque required for operation, which not only saves energy but also extends the lifespan of the valve, resulting in lower lifetime operational costs. Understanding these material and design distinctions helps industries optimize their systems for efficiency and reliability.

Related Posts

-

Exploring the Innovative Applications of Tube Fittings in Modern Engineering Solutions

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

Maximizing Efficiency: The Future of Hose Fittings in Industrial Applications

-

Understanding Gas Fittings: A Comprehensive Guide to Safety and Installation Best Practices

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency