- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

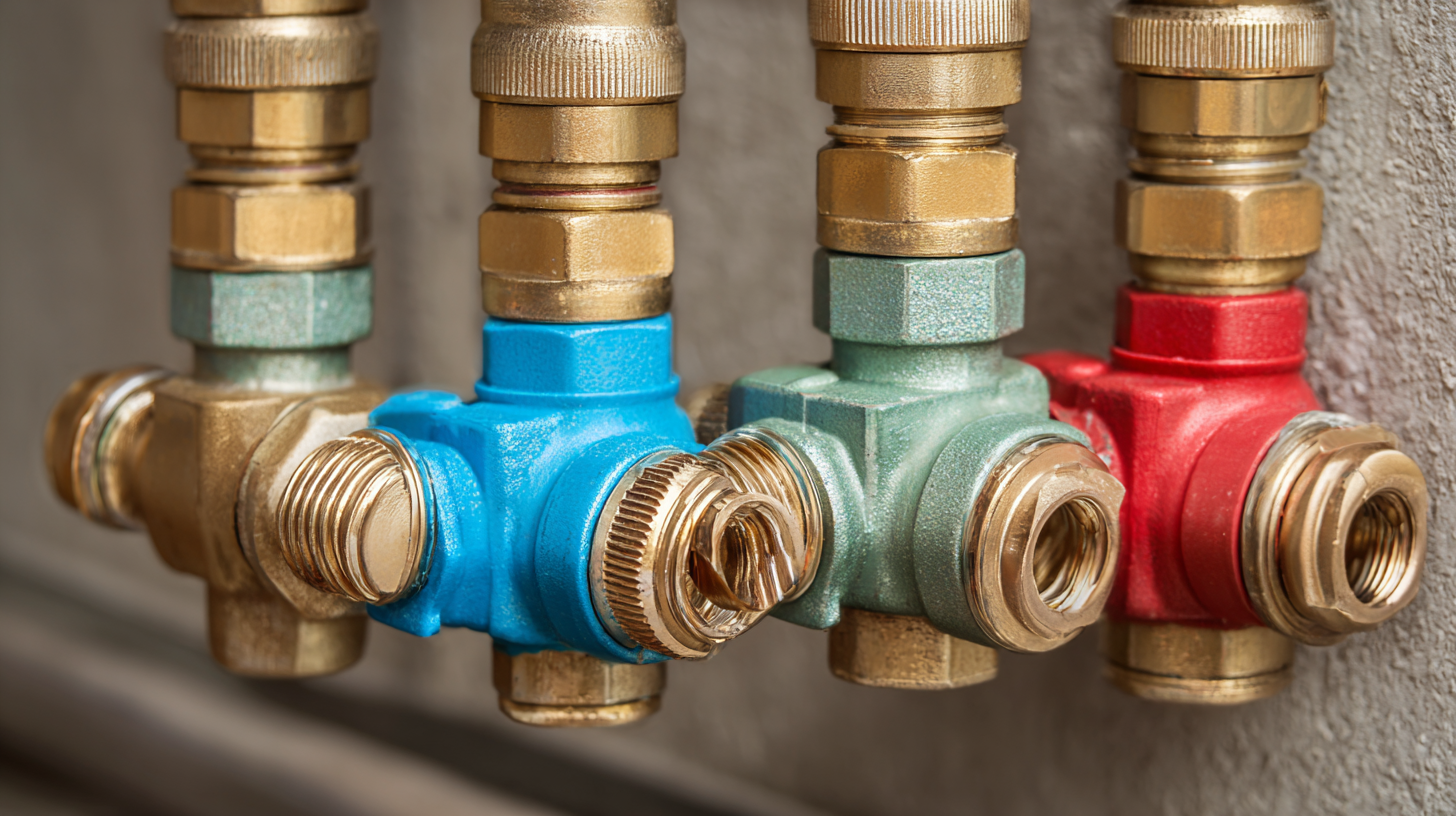

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency

Gas pipe fittings play a critical role in ensuring the safety and efficiency of gas systems in residential settings. According to the National Fire Protection Association (NFPA), improper installation or maintenance of gas piping can lead to catastrophic incidents, making it essential for homeowners to prioritize quality gas pipe fittings. A study by the American Gas Association indicates that using the correct fittings can improve system efficiency by up to 20%, significantly reducing energy costs. Moreover, the Consumer Product Safety Commission highlights that hundreds of gas-related injuries occur annually, largely attributable to faulty fittings and connections. With the increasing reliance on natural gas for heating and cooking, understanding the importance of reliable gas pipe fittings is paramount for safeguarding not only the home but also the well-being of its occupants.

This paper explores the various types of gas pipe fittings, their applications, and best practices for ensuring a safe and efficient gas piping system.

The Role of Gas Pipe Fittings in Ensuring Home Safety

Gas pipe fittings are crucial components in maintaining both safety and efficiency in residential systems. According to the National Fire Protection Association (NFPA), improper installation or failure of gas fittings is a leading cause of home gas leaks, which can result in explosive situations. Utilizing high-quality fittings ensures a reliable and secure connection throughout your gas system, significantly reducing the risk of leaks and enhancing overall safety in the home environment.

Tip: When selecting gas pipe fittings, always opt for those that meet local building codes and standards. Investing in certified fittings can provide peace of mind, ensuring that you are using materials designed to handle the pressure and flow of gas safely.

Furthermore, regular inspection and maintenance of gas pipe fittings can prevent potential hazards. The American Gas Association (AGA) recommends that homeowners periodically check their fittings and connections for signs of wear or corrosion. A proactive approach can not only prolong the lifespan of your gas system but also promote energy efficiency, reducing your overall energy costs while safeguarding your home.

Tip: Consider scheduling a professional inspection every couple of years to identify and address any potential issues before they escalate into serious problems.

Essential Types of Gas Pipe Fittings and Their Functions

Gas pipe fittings play a crucial role in ensuring the safety and efficiency of gas systems in residential settings. Among the essential types of fittings are elbows, tees, couplings, and valves.

Elbows facilitate directional changes in gas lines, allowing for flexible routing while maintaining the integrity of the system. According to a report by the American Society of Mechanical Engineers (ASME), properly installed pipe fittings can reduce energy loss by up to 15%, significantly enhancing overall system efficiency.

Tees and couplings are vital for connecting different pipes, ensuring a seamless flow of gas throughout the home. Tees allow for branch lines to be added without compromising the main gas supply, while couplings connect two segments of pipe securely. Furthermore, valves act as critical safety mechanisms, enabling users to shut off gas supply during emergencies or maintenance. The National Fire Protection Association (NFPA) emphasizes that malfunctioning fittings and valves account for approximately 28% of residential gas-related incidents. Therefore, understanding and investing in these fittings is essential for maintaining not just efficiency but also safety in home gas systems.

Common Installation Mistakes to Avoid with Gas Pipe Fittings

Gas pipe fittings play a crucial role in ensuring the safety and efficiency of home gas systems. However, improper installation can lead to serious hazards and inefficiencies. One common mistake is failing to adequately support gas pipework. According to the latest guidelines, including British Standard 6891: 2015 + A1 2019, ensuring that all gas pipework is properly supported is essential to prevent sagging or misalignment that could compromise gas flow and safety.

Gas pipe fittings play a crucial role in ensuring the safety and efficiency of home gas systems. However, improper installation can lead to serious hazards and inefficiencies. One common mistake is failing to adequately support gas pipework. According to the latest guidelines, including British Standard 6891: 2015 + A1 2019, ensuring that all gas pipework is properly supported is essential to prevent sagging or misalignment that could compromise gas flow and safety.

Tips: Always check for compliance with local regulations regarding pipework support. Ensure that fittings are installed with the correct spacing and support to maintain structural integrity. Additionally, it’s vital to use high-quality fittings specifically designed for gas applications to avoid leaks and potential hazards.

Another frequent error occurs during the installation of electrofusion fittings. Lessons learned from incidents highlight the importance of using electrofusion equipment correctly alongside proper installation techniques. Inadequate training or improper setup can lead to joint failures, which are dangerous in gas distribution systems.

Tips: Make sure everyone involved in the installation process is adequately trained in the use of electrofusion equipment. Regular inspections and adherence to installation protocols are crucial to maintain the safety of gas systems.

Regular Maintenance Tips for Long-Lasting Gas Pipe Fittings

Regular maintenance of gas pipe fittings is crucial for ensuring both safety and efficiency in the home. According to the National Fire Protection Association (NFPA), nearly 50% of home fires arise from malfunctioning gas systems, highlighting the essential role that well-maintained fittings play in preventing hazards. Homeowners should routinely inspect their gas fittings for any signs of wear, such as rust, corrosion, or leaks. The U.S. Department of Energy emphasizes that even small leaks can lead to significant energy loss, so regular checks can help conserve energy and reduce utility costs.

In addition to visual inspections, it is advisable to schedule professional maintenance at least once a year. The American Gas Association recommends that a qualified technician should examine all gas appliances and fittings, ensuring they meet safety regulations and function efficiently. Proper lubrication of connections and the tightening of fittings can prevent wear and tear, extending the life of the gas infrastructure. Investing time in maintenance not only enhances safety but can also lead to better overall performance of gas systems in homes.

The Impact of Quality Gas Pipe Fittings on Energy Efficiency

Gas pipe fittings play a crucial role in ensuring the safety and efficiency of gas systems within homes. According to a 2022 report by the American Gas Association, approximately 48% of American households rely on natural gas as their primary heating source, making the quality of gas pipe fittings more important than ever. High-quality fittings prevent leaks and provide a secure connection, significantly reducing the risks associated with gas usage. In fact, the National Fire Protection Association estimates that failure of gas piping systems contributes to 15% of residential gas incidents, highlighting the need for reliable and durable fittings.

Moreover, the quality of gas pipe fittings directly impacts energy efficiency. A study conducted by the U.S. Department of Energy revealed that well-installed and high-grade fittings can enhance the overall energy efficiency of gas appliances by up to 25%. This improvement not only lowers energy bills for homeowners but also reduces greenhouse gas emissions by preventing wastage of gas. Therefore, investing in quality gas pipe fittings is not merely a safety measure; it is also an essential step toward achieving better energy efficiency and environmental sustainability in residential settings.

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency - The Impact of Quality Gas Pipe Fittings on Energy Efficiency

| Feature | Impact on Safety | Impact on Efficiency | Recommended Material |

|---|---|---|---|

| Durability | Reduces risk of leaks and failures | Maintains gas flow integrity | Stainless Steel |

| Compatibility | Ensures safe fittings with existing systems | Maximizes system performance | Brass or Copper |

| Sealing Effectiveness | Prevents gas leaks | Improves energy consumption | PTFE (Teflon) Seals |

| Installation Ease | Reduces installation errors | Shorter installation time | Compression Fittings |

| Temperature Tolerance | Maintains safe operating conditions | Ensures efficiency under varying conditions | Carbon Steel |