- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

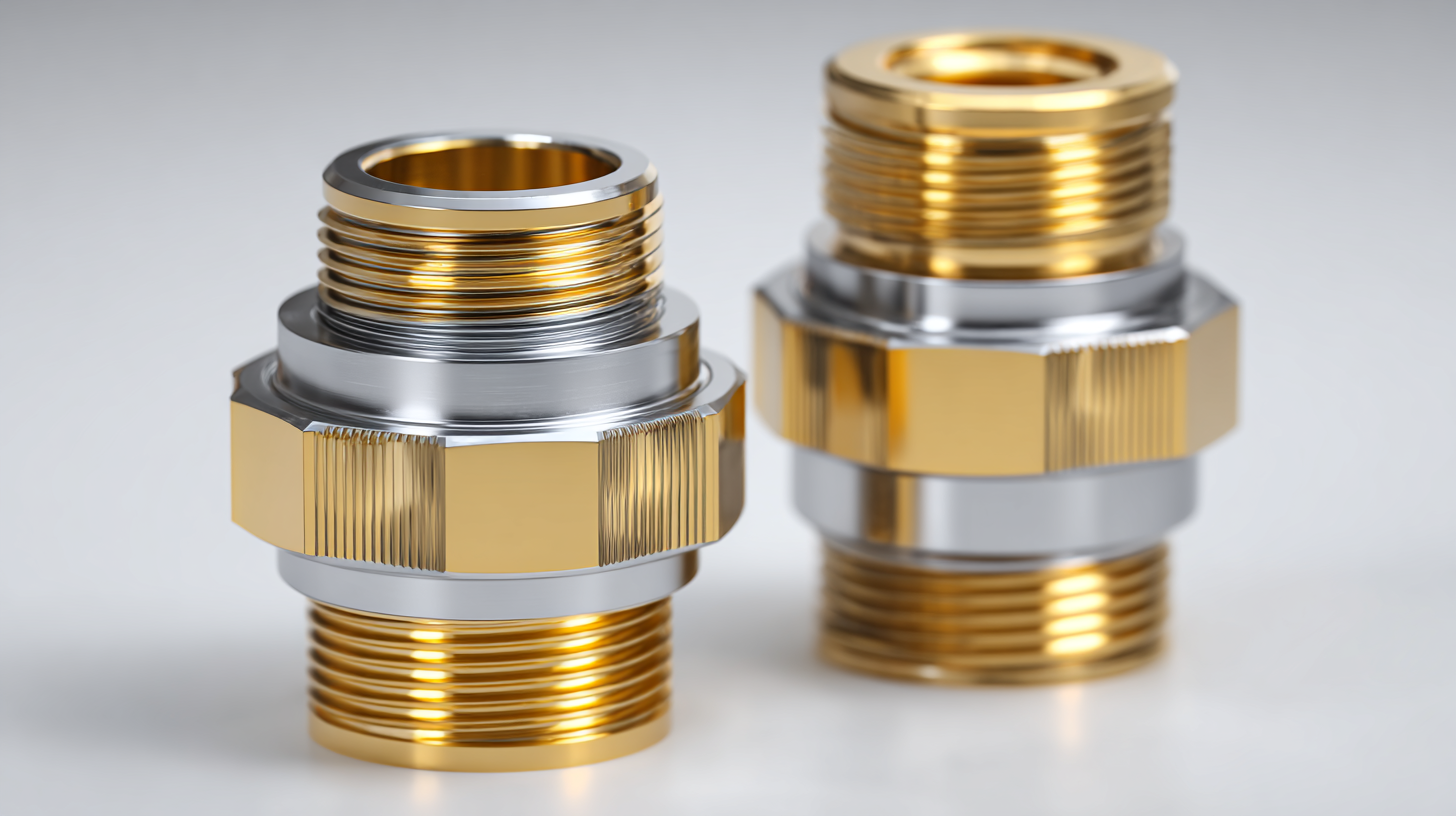

Exploring the Innovative Applications of Tube Fittings in Modern Engineering Solutions

In the ever-evolving landscape of modern engineering, tube fittings have emerged as essential components that enhance the efficiency and reliability of various systems. This article aims to explore the innovative applications of tube fittings across multiple industries, showcasing how they not only contribute to structural integrity but also streamline processes. As engineers continuously search for solutions that optimize performance and reduce costs, tube fittings serve as a versatile tool, facilitating seamless connections in pneumatic, hydraulic, and fluid handling systems. By examining the latest advancements and practical implementations of tube fittings, we will uncover the transformative potential these components hold in crafting sustainable and effective engineering solutions. Join us as we delve into the "how to" aspects of utilizing tube fittings to achieve superior results in contemporary engineering projects.

Innovative Design: How Tube Fittings Enhance Structural Integrity in Engineering

The utilization of tube fittings in modern engineering is revolutionizing structural integrity across various applications. Tube fittings, designed for secure connections in fluid and gas systems, enhance system reliability and performance. According to a report by Freedonia Group, the demand for tube fittings is projected to reach $2.5 billion by 2025, driven by advancements in manufacturing technology and increasing applications in sectors such as aerospace, automotive, and construction. These fittings provide engineers with the ability to create robust and adaptable systems that can withstand high pressures and extreme temperatures, thereby reducing the risk of leaks and failures.

Innovative design in tube fittings includes features such as easy assembly and disassembly, which facilitate maintenance and modifications in engineering applications. The use of materials such as stainless steel and high-performance plastics enhances corrosion resistance and durability, contributing to long-term sustainability in structures. A study from the National Institute of Standards and Technology (NIST) emphasizes that the right selection of tube fittings can result in a 20% increase in energy efficiency for fluid systems. This significant improvement underscores the vital role that tube fittings play in not only enhancing structural integrity but also optimizing operational performance in engineering projects.

Exploring the Innovative Applications of Tube Fittings in Modern Engineering Solutions - Innovative Design: How Tube Fittings Enhance Structural Integrity in Engineering

| Application Area | Material Type | Tube Fitting Type | Structural Benefit |

|---|---|---|---|

| Hydraulic Systems | Stainless Steel | Compression Fittings | High-pressure resistance |

| Automotive Industry | Aluminum | Push-to-Connect | Weight savings and flexibility |

| Aerospace Engineering | Titanium | Welded Fittings | Durability and corrosion resistance |

| Construction | Carbon Steel | Flared Fittings | Enhanced load-bearing capacity |

| Oil and Gas Industry | Alloy Steel | Swivel Fittings | Improved safety and leak prevention |

Efficiency Boost: The Role of Tube Fittings in Streamlining Manufacturing Processes

In modern engineering, tube fittings have emerged as a crucial component in optimizing manufacturing processes. These fittings offer seamless connections between different parts of a system, ensuring a secure and efficient flow of fluids or gases. By minimizing leaks and pressure drops, tube fittings enhance the performance of hydraulic and pneumatic systems, leading to increased operational efficiency. As companies strive to improve productivity and reduce costs, the integration of innovative tube fitting designs has proven to be a game changer.

Moreover, the versatility of tube fittings allows manufacturers to customize systems to meet specific operational needs. For instance, quick-connect fittings facilitate rapid assembly and disassembly, significantly reducing downtime during maintenance or upgrades. This adaptability not only streamlines workflows but also fosters a more agile manufacturing environment. By utilizing advanced materials and innovative engineering techniques, tube fittings contribute to the overall sustainability of production processes, making them an indispensable asset in the pursuit of efficiency within modern engineering solutions.

Versatility Unleashed: Applications of Tube Fittings in Diverse Engineering Fields

In modern engineering, tube fittings have emerged as essential components, demonstrating versatility across diverse fields such as aerospace, automotive, and marine engineering. According to a report by Grand View Research, the global tube fittings market is expected to reach $9.68 billion by 2025, driven by the increasing demand for efficient and reliable fluid transfer systems. This growth reflects the critical role tube fittings play in ensuring safety and performance in high-pressure and temperature environments.

In the aerospace sector, tube fittings are crucial for hydraulic and fuel systems, where reliability is paramount. The Federal Aviation Administration (FAA) indicates that approximately 70% of aviation accidents are attributed to equipment failure, underlining the importance of dependable fittings in maintaining system integrity. Similarly, in the automotive industry, advancements in vehicle design increasingly incorporate lightweight materials, necessitating tube fittings that are not only durable but also compatible with various fluid types.

The International Organization of Motor Vehicle Manufacturers (OICA) projects a steady increase in automobile production, further bolstering the demand for innovative tube fitting solutions that enhance efficiency and performance in modern engineering applications.

Sustainability Focus: The Impact of Tube Fittings on Eco-Friendly Engineering Solutions

The incorporation of tube fittings in modern engineering solutions is increasingly recognized for its sustainability benefits, significantly impacting eco-friendly practices across industries. According to a report by the International Energy Agency (IEA), the efficiency of fluid transport systems can be enhanced by up to 30% when utilizing optimized tube fittings, which minimizes energy loss and reduces the overall carbon footprint. This not only aligns with global sustainability goals but also represents a cost-effective strategy for companies aiming to lower operational expenses.

Moreover, the use of advanced materials in tube fittings, such as high-strength alloys and recycled plastics, contributes to enhanced durability and a reduced need for resource consumption. A recent study published by the American Society of Mechanical Engineers (ASME) indicated that replacing traditional fittings with innovative, standardized tube fittings can decrease waste generation by approximately 20% during manufacturing processes. This commitment to resource efficiency supports engineering firms in achieving their sustainability targets while meeting regulatory standards for environmental responsibility. As the industry evolves, the ongoing development and application of tube fittings will play a critical role in fostering a greener future.

Impact of Tube Fittings on Eco-Friendly Engineering Solutions

Safety First: Enhancing System Reliability with Advanced Tube Fitting Technologies

In modern engineering solutions, the emphasis on safety and reliability has never been greater, particularly in sectors such as aerospace, oil and gas, and automotive. Advanced tube fitting technologies play a pivotal role in enhancing system reliability by providing robust connections that can withstand extreme pressure and temperature conditions. Research indicates that failures in fluid systems, often due to inadequate fittings, can lead to catastrophic incidents, making the reliability of these components crucial. According to a report by the Fluid Power Society, approximately 20% of hydraulic system failures are attributed to faulty fittings, highlighting the importance of investing in quality tube fitting solutions.

The innovation in tube fitting technology integrates materials engineered for greater resilience, such as stainless steel and high-density polymers, which significantly reduce the risk of leaks and ruptures. For instance, the global market for advanced tube fittings is projected to reach $12 billion by 2025, driven by the demand for enhanced performance and safety standards across industries. Advanced designs, including multi-seal systems and quick-connect fittings, offer improvements in installation efficiency, further mitigating the risks associated with human error. By leveraging these technologies, engineers are better equipped to ensure the integrity and safety of their systems, ultimately meeting stringent compliance norms and enhancing operational efficiency.

Related Posts

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency

-

Exploring Quick Connectors: The Unsung Heroes of Efficient Plumbing and Wiring Solutions

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

Innovative Applications for Tubing Connectors in Modern Industries

-

Maximizing Efficiency: The Future of Hose Fittings in Industrial Applications

-

Essential Plumbing Fittings Every DIY Enthusiast Should Know About