- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

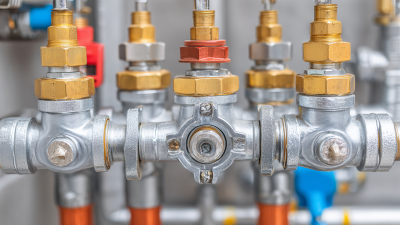

Top 10 Ball Valves for Industry Use: Key Features, Trends, and Market Insights for 2024

As the industrial landscape evolves, the demand for efficient and reliable flow control mechanisms becomes increasingly prominent. Ball valves, known for their robust performance and versatility, play a pivotal role in various applications ranging from oil and gas to water treatment. According to the latest market research report by Research and Markets, the global ball valve market is projected to reach approximately $12 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.4% from 2024. This surge is driven by advancements in technology and a growing emphasis on operational efficiency in industrial processes.

In light of these trends, we delve into the top 10 ball valves set to dominate industrial use in 2024 and beyond. Key features such as durability, low torque requirements, and superior sealing capabilities are critical in selecting the right valve for specific applications. Moreover, market insights reveal a continuing shift towards automation and IoT integration, which will influence the design and functionality of ball valves. As industries prioritize sustainability and energy efficiency, understanding the evolving landscape of ball valves will be essential for stakeholders aiming to optimize their operations and meet regulatory demands.

Key Considerations for Selecting the Best Industrial Ball Valves in 2024

When selecting the best industrial ball valves in 2024, several key considerations come into play. Firstly, understanding the specific application and operating conditions is crucial. Factors such as the type of fluid being transported, temperature ranges, and pressure requirements significantly influence the valve material and design choice. According to the ISA-96 series of standards, adherence to established specifications ensures reliable performance and longevity of valve actuators, which are essential for optimal valve functionality in demanding environments.

Moreover, industry trends suggest increasing demand for automation and smart technology integration in valve systems. The global pump and valve markets have experienced fluctuations, notably influenced by changing oil prices and sustainability initiatives.

It's projected that the adoption of advanced monitoring and control technologies will enhance operational efficiency, making it vital to consider these innovations when selecting valves. Comprehensive market insights indicate that end-users prioritize reliability, performance, and maintainability, aligning with the evolving landscape of industrial needs in 2024.

Emerging Trends in Ball Valve Technology and Their Industry Impact

The ball valve market is experiencing significant transformation, driven by emerging technologies and increasing demand across various industries. One of the prominent trends is the integration of smart valve technologies, allowing for enhanced automation and remote monitoring capabilities. These advancements improve operational efficiency and reduce maintenance costs, positioning smart ball valves as a vital component in sectors such as oil and gas, water treatment, and chemical processing.

Additionally, sustainability and environmental concerns are reshaping the industry landscape. Manufacturers are increasingly focusing on producing eco-friendly valves, with materials that minimize leakage and optimize resource usage. The shift towards more sustainable practices not only meets regulatory requirements but also addresses the growing demand for greener operations. As industries prepare for 2024, the focus on innovation and sustainable solutions in ball valve technology will continue to forge new pathways, driving substantial market growth.

Comparative Analysis of Material Types Used in Ball Valves for Durability

When evaluating ball valves for industrial use, the materials employed in their construction play a crucial role in determining durability and performance. Common materials include stainless steel, brass, and plastic, each offering distinct advantages for different applications. For instance, stainless steel is renowned for its strength and corrosion resistance, making it ideal for harsh environments where exposure to chemicals is a concern. On the other hand, brass provides excellent durability at a lower cost, suitable for less corrosive applications. Plastic ball valves, often used in water treatment and low-pressure scenarios, offer excellent resistance to corrosion but may not withstand extreme pressures.

Current trends indicate a growing preference for advanced composite materials in ball valve design. These materials combine the beneficial properties of traditional metals and plastics, resulting in lighter, stronger, and more chemically resistant valves. The introduction of such materials not only enhances durability but also contributes to energy efficiency in systems. As industries shift towards sustainability, the demand for innovative and durable valve materials is expected to rise, influencing future designs and manufacturing processes. The comparative analysis of these material types highlights the necessity of selecting the right balance between cost, durability, and application needs in the ever-evolving industrial landscape.

Market Insights: Demand Forecast and Supply Chain Dynamics in 2024

In 2024, the demand for ball valves in various industries is projected to grow significantly, driven by advancements in supply chain dynamics and the need for efficient fluid control solutions. Market insights indicate that the global sustainable supply chain finance market is expected to reach approximately USD 7,735.58 million by 2034, growing at a CAGR of 8.15%. This highlights the urgency for industries to embrace sustainable practices, ensuring that their operations can adapt to changing market conditions.

As companies navigate complexities and recover from the disruptions caused by COVID-19, implementing AI technologies becomes crucial. The AI in supply chain market, valued at USD 7.15 billion in 2024, is anticipated to surpass USD 192.51 billion by 2034. This trend underscores the importance of integrating AI to enhance operational efficiency and resilience.

Tips: To stay ahead of the curve, companies should invest in digital twins to optimize their supply chain processes and consider leveraging AI tools for real-time data analysis. Additionally, maintaining close relationships with suppliers can mitigate risks associated with supply chain disruptions, ensuring a robust operational framework in the evolving market landscape.

Top Manufacturers in the Ball Valve Market: Key Players and Innovations

The ball valve market is witnessing significant evolution, driven by innovations from key manufacturers. Industry leaders such as Emerson, Valmet, and Cameron are not only enhancing valve durability and performance but are also integrating smart technologies. These advancements enable remote monitoring and diagnostics, allowing for more efficient operations in various industrial applications. Emerson, for instance, has introduced advanced automation features that optimize valve control, ensuring precision and reliability in critical systems.

Additionally, manufacturers are focusing on sustainability and energy efficiency in their product designs. Innovations such as low-emission valves and eco-friendly manufacturing processes are becoming increasingly important as industries strive to reduce their environmental impact. Companies like Flowserve and Kitz are at the forefront, developing products that comply with international environmental standards while meeting the stringent requirements of modern industrial applications. As the market evolves, these manufacturers continue to set the pace by offering state-of-the-art solutions that cater to diverse industry needs, highlighting their commitment to innovation and sustainability.

Top 10 Ball Valves for Industry Use in 2024

This chart illustrates the projected market distribution of the top ten ball valve types used in industry for the year 2024. The data includes common types, their estimated market share, and highlights key trends in the industry.

Related Posts

-

Understanding the Importance of Ball Valves in Modern Industrial Applications

-

Exploring Quick Connectors: The Unsung Heroes of Efficient Plumbing and Wiring Solutions

-

The Ultimate Guide to Choosing the Best Air Hose for Your Workshop

-

Innovative Applications for Tubing Connectors in Modern Industries

-

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

-

Understanding Gas Fittings: A Comprehensive Guide to Safety and Installation Best Practices