- Menu

- Skip to right header navigation

- Skip to main content

- Skip to secondary navigation

- Skip to footer

- Products

-

-

- Fittings

- Hy-Lok Tube Fittings

- 24° Tube Fittings – DIN 2353 & ISO 8434-1

- 37° Flared Tube Fittings – SAE J514 & ISO 8434-2

- Instrument thread & Weld Fittings

- RS Fittings

- Hose Fittings for JIS/KS

- Push On Hose Connectors

- ZCO O-Ring Face Seal Fittings

- Pipe Fittings for ASME B16.11

- Tube butt weld fittings

- ZCR Metal Gasket Face Seal Fittings

- Ultra High Purity Fittings

- Flanges

- Flange connectors

- Fittings

-

- Services

- Resources

- Blog

- About us

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

When embarking on industrial projects, selecting the right high pressure fittings is crucial for ensuring safety, performance, and reliability in fluid transfer systems. According to a report by MarketsandMarkets, the global high pressure fittings market is projected to reach USD 3.9 billion by 2025, growing at a CAGR of 6.2% from 2020. This increasing demand underscores the importance of making informed choices when it comes to materials, sizes, and configurations of high pressure fittings. Ensuring compatibility with system specifications not only enhances operational efficiency but also minimizes the risks of leaks and failures in high-stress environments. In this comprehensive guide, we explore the essential considerations for choosing high pressure fittings that cater to your specific project requirements, backed by industry insights and best practices to ensure optimal performance.

Understanding the Basics of High Pressure Fittings and Their Applications

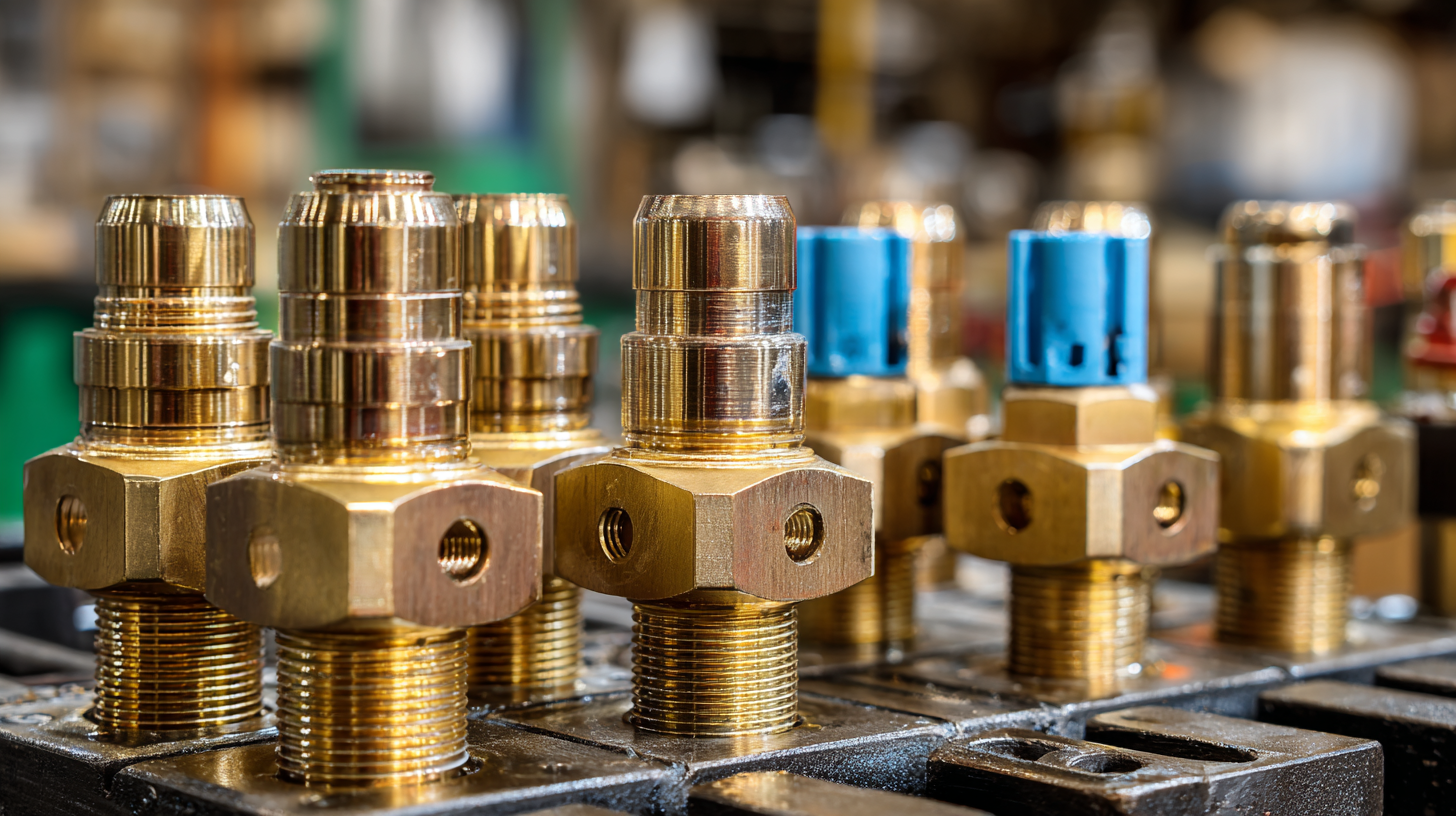

High pressure fittings are critical components in various industrial applications, designed to withstand extreme pressure and ensure the safe transfer of fluids and gases. Understanding the basics of these fittings is essential for selecting the right components for your project. These fittings come in various types, including elbows, tees, couplings, and reducers, each serving a unique purpose and application. It's important to know the material of the fittings, which can range from stainless steel to brass, as this determines their compatibility with different substances and their overall durability.

High pressure fittings are critical components in various industrial applications, designed to withstand extreme pressure and ensure the safe transfer of fluids and gases. Understanding the basics of these fittings is essential for selecting the right components for your project. These fittings come in various types, including elbows, tees, couplings, and reducers, each serving a unique purpose and application. It's important to know the material of the fittings, which can range from stainless steel to brass, as this determines their compatibility with different substances and their overall durability.

The applications of high pressure fittings stretch across multiple industries, including oil and gas, chemical processing, and water supply systems. For instance, in the oil and gas sector, fittings are used in pipelines to transport crude oil and natural gas under high pressure. In chemical processing, they facilitate the transfer of corrosive substances safely. This versatility highlights the importance of selecting the right fitting for each specific application, taking into account factors like pressure ratings, temperature limits, and resistance to specific chemicals. By familiarizing yourself with these basics, you can make informed decisions that enhance the efficiency and safety of your projects.

Key Factors to Consider When Selecting High Pressure Fittings

When selecting high pressure fittings for your projects, several key factors must be taken into consideration to ensure optimal performance and safety. One important aspect is the material of the fitting. Options such as stainless steel, brass, and carbon steel each have their own strengths and weaknesses, particularly in terms of corrosion resistance, temperature tolerance, and pressure ratings. Assessing the specific conditions under which the fittings will operate is crucial. For instance, in environments exposed to harsh chemicals, a corrosion-resistant material may be essential.

Another significant factor to consider is the compatibility with existing systems. High pressure fittings must align with the specifications of the piping or equipment they will connect to, including dimensions and threading. Mismatched fittings can lead to leaks and catastrophic failures. Additionally, understanding the required pressure ratings is vital; selecting fittings that can withstand the operational pressure without risk of failure is crucial for safety and reliability. Proper evaluation of these factors will lead to better selection and performance of high pressure fittings in any project.

Material Selection: Choosing the Right Type for Durability and Compatibility

When selecting high-pressure fittings, material selection plays a crucial role in ensuring both durability and compatibility with the fluids involved. According to a report by the Global High-Pressure Fittings Market, the choice of material affects not only the lifespan of the components but also their performance under extreme conditions. For instance, stainless steel remains a popular choice due to its excellent resistance to corrosion and high strength. As per industry standards, fittings made from stainless steel 316 are specifically recommended for environments with harsh chemicals, showing a corrosion resistance rate exceeding 85% compared to carbon steel fittings in similar applications.

In contrast, plastics like polyvinyl chloride (PVC) and Teflon (PTFE) are increasingly being used in high-pressure systems that handle corrosive substances. A study published in the Journal of Fluid Mechanics indicates that high-density polyethylene (HDPE) fittings can maintain integrity under pressures of up to 1500 psi, making them suitable alternatives for many industrial applications. Moreover, compatibility with the conveyed medium is paramount; materials must be selected based on their chemical properties to prevent degradation and failure. This careful consideration of material selection is indispensable for achieving optimal performance and safety in high-pressure systems.

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

| Material Type | Applications | Temperature Range (°C) | Pressure Rating (PSI) | Corrosion Resistance |

|---|---|---|---|---|

| Stainless Steel | Oil & Gas, Chemical Processing | -50 to 400 | 10,000 | Excellent |

| Carbon Steel | Water Supply, HVAC Systems | -20 to 250 | 5,000 | Good |

| Brass | Plumbing, HVAC | -40 to 200 | 3,000 | Moderate |

| Plastic (PVC) | Chemical Transport, Water Systems | 0 to 60 | 1,000 | Poor |

| Titanium | Aerospace, Marine Applications | -50 to 600 | 15,000 | Excellent |

Safety Standards and Regulations for High Pressure Fittings

When selecting high pressure fittings for your projects, understanding safety standards and regulations is crucial. Industry reports indicate that improper fittings can lead to failures resulting in equipment damage and safety hazards. According to the American Society of Mechanical Engineers (ASME), up to 30% of pressure-related accidents are attributed to substandard fittings. Therefore, adhering to rigorous standards such as ASME B31.3 (Process Piping) and ASTM standards ensures not only performance but also compliance with safety regulations.

Tips: Always verify that the fittings you select are certified by recognized standards organizations. Check for markings indicating compliance with ASME or API (American Petroleum Institute) specifications, which signify that the fittings have met stringent safety protocols.

In addition, it's vital to conduct regular inspections and maintenance on high pressure systems. The National Fire Protection Association (NFPA) recommends a checklist approach for routine checks, focusing on signs of wear or corrosion that could compromise the integrity of the fittings. By implementing a proactive maintenance strategy, you can significantly reduce the risk of equipment failure and enhance the safety of your operations.

Tips: Utilize pressure gauges and monitors to keep track of system performance. Regularly review system pressure levels against the specifications marked on your fittings to ensure you're operating within safe limits.

Common Mistakes to Avoid When Choosing High Pressure Fittings

When selecting high-pressure fittings for your projects, avoiding common pitfalls can save time, money, and frustration. One frequent mistake is neglecting to thoroughly assess the compatibility of materials with the working environment. High-pressure systems are often exposed to various chemicals and temperatures, and using mismatched materials can lead to corrosion or failure of fitments. Always ensure that the fittings you choose can withstand the specific pressures, temperatures, and corrosive elements they will encounter.

Another common error is overlooking the importance of proper sizing. High-pressure fittings come in a range of sizes, and choosing the wrong size can disrupt flow rates and increase the risk of leaks. It’s crucial to measure accurately and consult manufacturer specifications to guarantee that you have the right dimensions for your application. Additionally, many users underestimate the significance of getting professional advice. Consulting with experts can provide valuable insights that enhance your decision-making process and help you select the most suitable fittings for your high-pressure needs.

The Ultimate Guide to Choosing the Right High Pressure Fittings for Your Projects

This chart highlights the common mistakes that people make when choosing high pressure fittings for their projects, with a focus on various critical factors such as material quality, pressure rating, and application suitability.

Related Posts

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

Maximizing Efficiency: The Future of Hose Fittings in Industrial Applications

-

The Ultimate Guide to Choosing the Right Hose and Fittings for Your Project

-

Understanding the Importance of Gas Pipe Fittings in Home Safety and Efficiency

-

Innovative Applications for Tubing Connectors in Modern Industries